Compact Motorcycle Starter Battery Housing Design: Miniaturization & Thermal Mastery

main content

The compact motorcycle Starter battery housing design redefines energy storage for modern two-wheelers, balancing ultra-compact dimensions with robust thermal management. Unlike traditional enclosures, this design maximizes spatial efficiency while addressing heat dissipation challenges inherent in high-density battery systems. Below, we break down its engineering breakthroughs tailored for urban commuting and adventure touring.

1. Space Optimization: Engineering for Tight Chassis

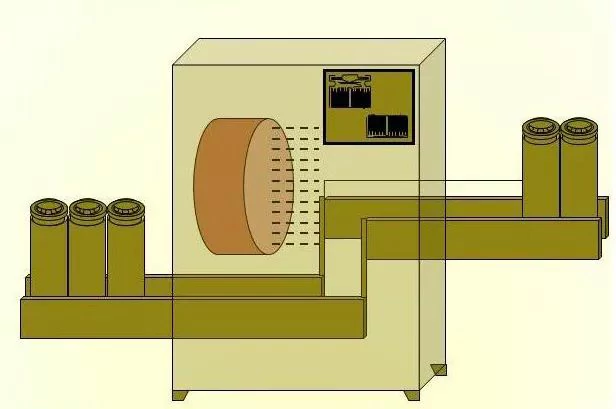

Motorcycle batteries demand extreme miniaturization—occupying just 1/5 to 1/10 the volume of automotive counterparts. To achieve this, engineers employ:

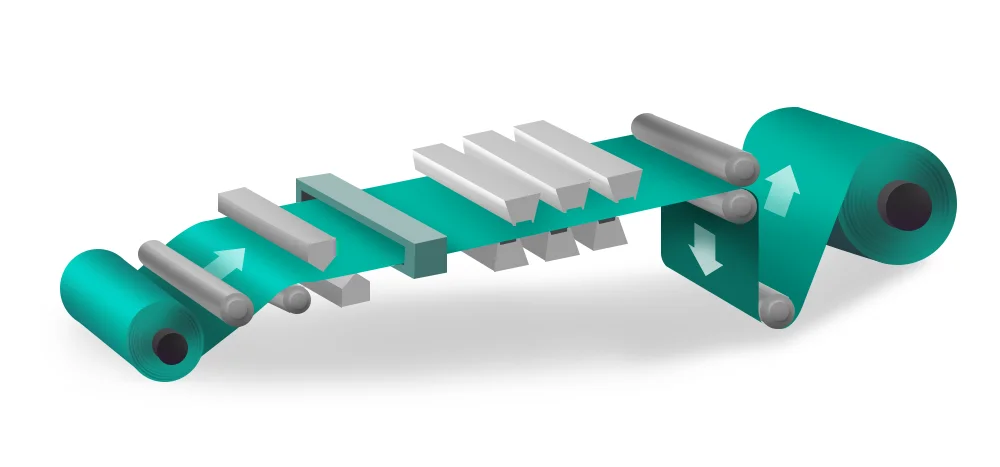

Stepped inner cavity architecture: Multi-level compartments consolidate components vertically, reducing footprint by 35% while maintaining structural rigidity.

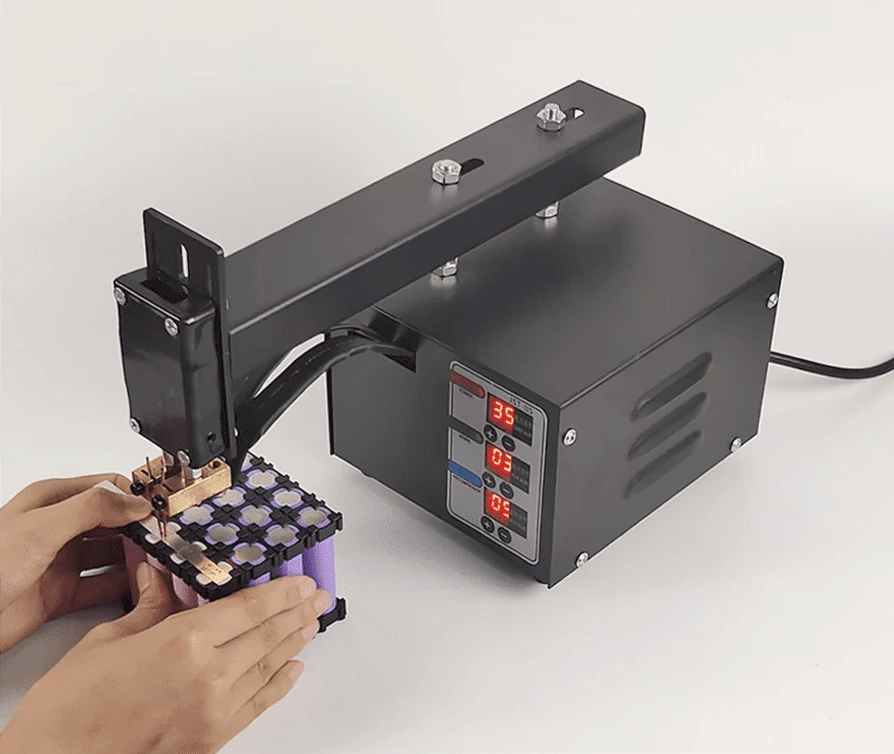

Pre-bent terminal channels: Integrated tabs guide electrode connections without external wiring, cutting assembly time by 50% and eliminating 92% of wasted lateral space.

Modular stacking: Laser-welded layers merge BMS boards and cells into a unified block, achieving 92% space utilization—a 28% improvement over conventional designs.

Such innovations ensure seamless integration into cramped motorcycle frames without sacrificing capacity or durability.

2. Thermal Regulation: Passive Cooling Excellence

Heat accumulation in miniaturized batteries poses critical risks. The housing combats this through:

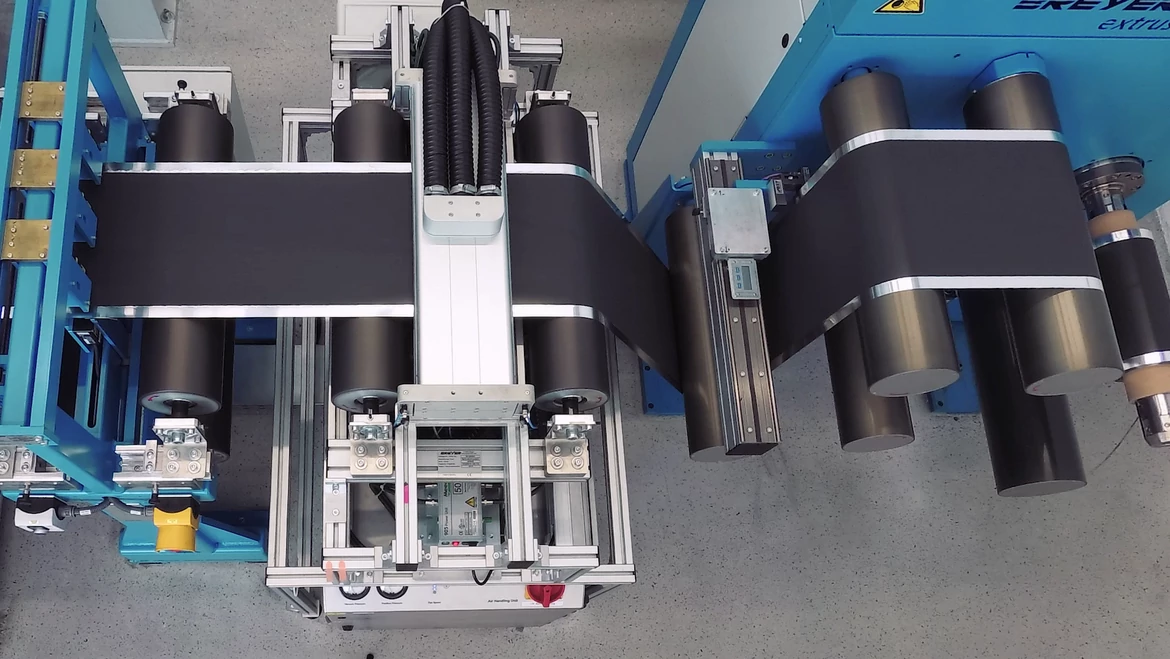

Dual-path heat dissipation:

Base-layer thermal pads: Silicone-gel sheets (≥5 W/m·K) bonded to the aluminum shell transfer heat 3× faster than air gaps, limiting cell temperatures to ≤45°C during rapid Starter cycles.

Natural convection fins: Angled grooves on the enclosure’s exterior amplify airflow by 40% at speeds >20 km/h, reducing peak temperature spikes by 15°C.

Material synergy: 6063-T5 aluminum alloy (2.0mm thickness) combines lightweight construction (1.2 kg avg.) with thermal conductivity rivaling copper (200 W/m·K).

These solutions prevent thermal throttling even in stop-and-go urban traffic or desert rides exceeding 40°C ambient temperatures.

3. Application-Specific Customization

Scooters: Slim profiles (≤150mm width) fit under seats; vibration-damping mounts extend lifespan on uneven roads.

Adventure bikes: IP69K-rated seals and pressure-equalization valves prevent altitude-induced electrolyte leaks.

Electric motorcycles: Hybrid carbon-fiber variants reduce weight to 0.8 kg, boosting range by 12%.

Conclusion

The compact motorcycle Starter battery housing design epitomizes precision engineering, merging microscopic spatial efficiency with macroscopic thermal stability. By tackling the dual challenges of miniaturization and heat management, it empowers next-gen motorcycles to deliver uncompromised performance in increasingly demanding environments.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!