BMS MOSFET Switch Materials

main content

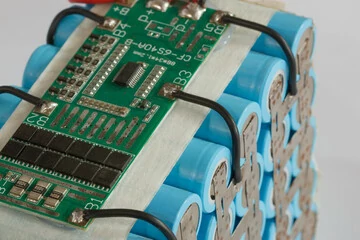

BMS MOSFET switch materials are pivotal to ensuring robust protection and operational efficiency in motorcycle lithium starting batteries. These materials govern thermal management, current regulation, and voltage stability, directly impacting safety during high-stress scenarios like engine cranking or rapid charging. By integrating advanced semiconductor alloys and durable packaging, modern BMS designs deliver precision control over critical electrical parameters. This article examines the core materials, their functional roles, and design strategies tailored for demanding motorcycle environments.

Core Materials in BMS MOSFET Protection Circuits

1.Silicon vs. Silicon Carbide (SiC) MOSFETs

Silicon MOSFETs remain widely used for their cost efficiency and reliability. In contrast, silicon carbide (SiC) variants excel in high-temperature environments due to enhanced thermal conductivity (up to 3x higher than silicon) and reduced energy loss—critical for motorcycles exposed to engine heat.

2.Gate Oxide Layer

A silicon dioxide (SiO₂) layer insulates the gate terminal, minimizing leakage currents. High-purity oxides ensure stable voltage thresholds (±2% tolerance), preventing false triggering during voltage spikes.

3.Packaging Components

Copper-based TO-247 or D²PAK housings with epoxy resins optimize heat dissipation and mechanical strength. These materials withstand vibrations up to 20G, common in off-road motorcycles.

4.Thermal Interface Materials (TIMs)

Ceramic-filled silicone pads or graphene-enhanced films bridge MOSFETs and heatsinks, reducing thermal resistance by 15–30%. This prevents overheating during sustained high-current operations.

5.Auxiliary Circuitry

TVS Diodes: Silicon avalanche diodes clamp transient voltages from starter motors.

Snubber Circuits: High-temperature RC networks suppress voltage oscillations during MOSFET switching.

Performance Benefits of Optimized Materials

High Current Tolerance: Low RDS(on) silicon MOSFETs handle 400A surges, while SiC versions endure 700A pulses without failure.

Voltage Precision: Engineered gate oxides maintain ±5% voltage thresholds, crucial for 12V/24V motorcycle systems.

Thermal Endurance: Copper-clad PCBs and ceramic substrates enable stable operation at 150°C, even in compact battery compartments.

Design Strategies for Motorcycle BMS

1.Vibration Resistance

Spring-mounted MOSFETs and conformal-coated PCBs prevent solder fatigue under continuous shocks.

2.Environmental Protection

Silicone gel encapsulation blocks moisture and dust ingress, meeting IP67 standards for rugged use.

3.Fast Fault Response

Self-monitoring gate drivers reset MOSFETs within 10μs after transient overloads, ensuring uninterrupted cranking.

4.Energy Efficiency

Low-quiescent-current MOSFETs (<2μA standby drain) extend battery life during storage.

Conclusion

BMS MOSFET switch materials are the cornerstone of reliable lithium battery systems in motorcycles. From silicon carbide’s thermal superiority to vibration-resistant packaging, each material addresses the unique challenges of high-power, compact applications. Innovations like wide-bandgap semiconductors and adaptive cooling interfaces will further enhance safety, positioning MOSFETs as indispensable components in next-generation battery management.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!