BMS MOSFET Protection Circuit

main content

The BMS MOSFET protection circuit is the cornerstone of safety and efficiency in modern motorcycle lithium starting batteries. By integrating high-performance MOSFET switches and intelligent control logic, this circuit prevents critical failures like overcharging, over-discharging, and short circuits. Below, we dissect its structure, operational principles, and design considerations tailored for high-demand motorcycle applications.

Core Components of the Protection Circui

1.MOSFET Switches

MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) act as rapid-response electronic switches. In motorcycle BMS, N-channel MOSFETs are typically used due to their low on-resistance (RDS(on)) and high current-handling capabilities. These switches control the battery’s charge/discharge paths by opening or closing based on real-time voltage, current, and temperature data. Dual MOSFETs are often arranged in a back-to-back configuration to block reverse currents and prevent accidental activation of the body diode.

2.Gate Driver ICs

Specialized driver ICs (e.g., LM5109B-Q1) amplify control signals from the BMS microcontroller to ensure fast MOSFET switching. They provide sufficient gate-source voltage (VGS) to minimize switching losses and thermal stress. High-speed drivers reduce propagation delays to nanoseconds, critical for protecting against sudden short circuits.

3.Current & Voltage Sensors

Precision shunt resistors or Hall-effect sensors monitor battery current, while voltage dividers track individual cell voltages. These sensors feed data to the BMS microcontroller, triggering MOSFET shutdown if thresholds are exceeded (e.g., >60V for overvoltage or <2.9V for undervoltage).

4.Thermal Management Elements

Thermistors or digital temperature sensors embedded near MOSFETs detect overheating. If temperatures exceed safe limits (e.g., 150°C), the BMS disables MOSFETs and activates fail-safe protocols. Heat sinks or thermal pads dissipate heat during high-load scenarios like engine cranking.

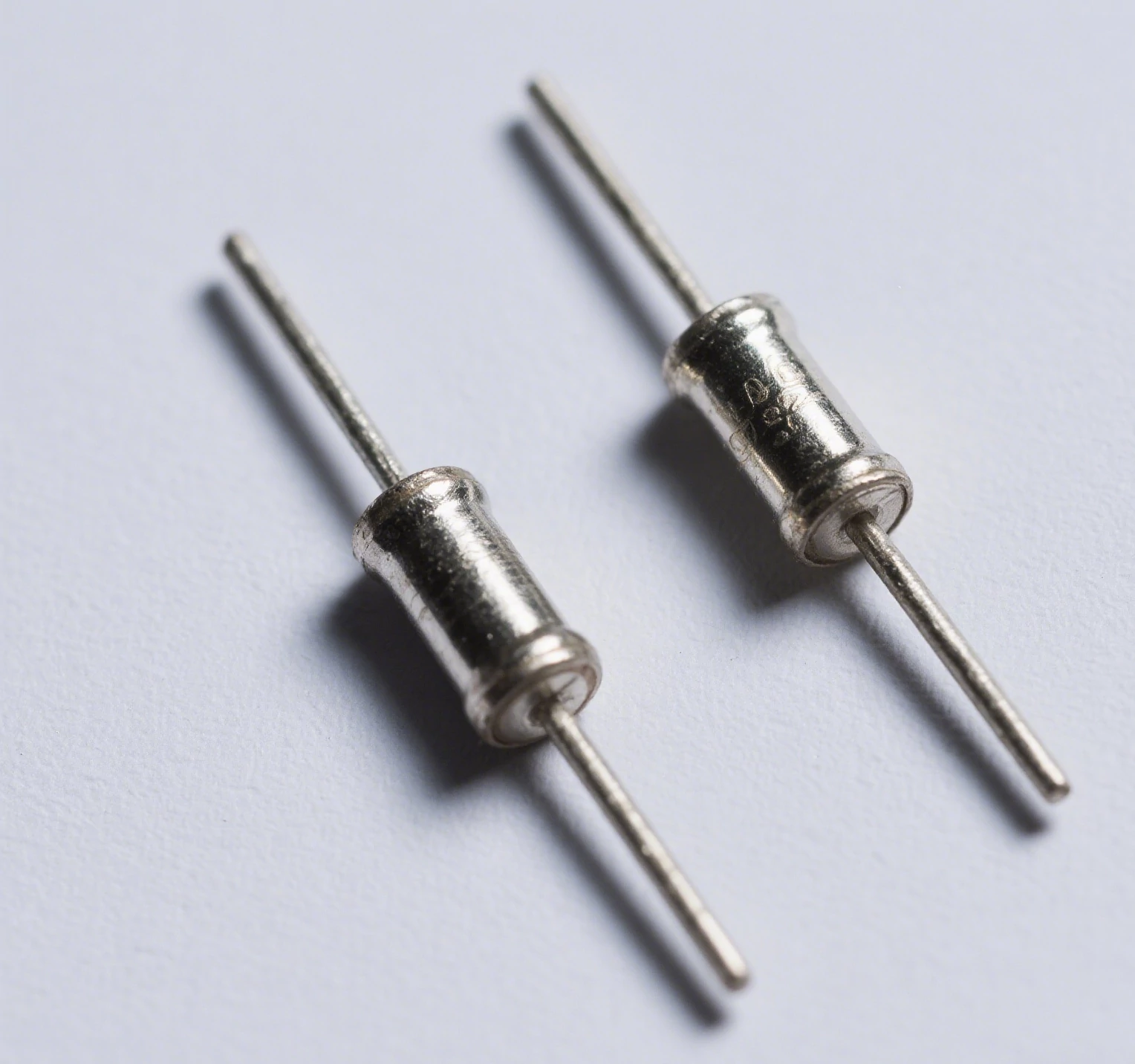

5.Auxiliary Protection Modules

TVS Diodes: Suppress voltage spikes from inductive loads (e.g., starter motors).

RC Snubbers: Dampen ringing effects during MOSFET switching.

Fuses: Provide secondary overcurrent protection if MOSFETs fail.

Key Functions in Motorcycle Applications

Overcurrent/Short-Circuit Protection:

During a short circuit, MOSFETs shut down within microseconds to limit peak currents. For example, a 100A-rated MOSFET can withstand transient surges up to 762A for 15μs (per UIS testing), preventing catastrophic battery damage.

Voltage Threshold Control:

MOSFETs isolate the battery when cell voltages deviate beyond ±5% of nominal levels. Active balancing circuits may redistribute energy between cells to maintain uniformity.

Reverse Polarity Prevention:

Back-to-back MOSFET configurations block reverse currents, ensuring the battery isn’t damaged by incorrect jumper cable connections.

Thermal Derating:

Dynamic current limits adjust based on real-time MOSFET temperature, allowing maximum power during cold starts while avoiding thermal runaway in high-heat environments.

Design Considerations for Motorcycle BMS

1.Vibration Resistance:

Spring-loaded connectors and conformal-coated PCBs withstand motorcycle vibrations up to 20G.

2.Low-Power Operation:

Quiescent currents below 2μA prevent battery drain during idle periods.

3.Voltage Compatibility:

MOSFETs rated for 60V–100V cover common 12V/24V systems and handle regenerative voltage spikes.

4.Fast Fault Recovery:

Auto-retry mechanisms reactivate MOSFETs after transient faults, ensuring uninterrupted operation.

Conclusion

The BMS MOSFET protection circuit is indispensable for optimizing the reliability and lifespan of motorcycle lithium starting batteries. From precision current sensing to ruggedized thermal management, each component is engineered to meet the extreme demands of applications. As battery technology evolves, innovations in wide-bandgap semiconductors (e.g., SiC MOSFETs) and adaptive algorithms will further elevate safety standards, solidifying MOSFETs as the backbone of next-generation energy management systems.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!