BMS communication interface module materials for motorcycle batteries

main content

The BMS communication interface module materials for motorcycle batteries are pivotal in ensuring reliable data exchange, safety, and longevity. Designed to withstand harsh environments, these materials directly impact the module’s performance in heat management, electromagnetic interference (EMI) resistance, and electrical stability. Below, we explore the core materials used and their roles in optimizing functionality.

Key Material Categories and Their Functions

1. Conductive Materials

Conductive components form the backbone of signal transmission. Copper and aluminum alloys are widely used for wiring and circuit traces due to their high electrical conductivity and cost-effectiveness. Silver-coated contacts enhance conductivity in high-frequency communication ports, reducing signal loss. Additionally, conductive polymers are employed in flexible circuits to balance lightweight design and durability.

2. Insulation and Encapsulation Materials

Thermosetting plastics like epoxy resins provide insulation for PCBs, preventing short circuits and moisture ingress. Silicone gels or polyurethane coatings encapsulate sensitive components, offering thermal stability and vibration resistance—critical for motorcycles exposed to dynamic mechanical stress.

3. EMI Shielding Components

Electromagnetic interference can disrupt data integrity. Conductive shielding materials such as aluminum foil, nickel-coated fabrics, or metalized films are layered around circuits to absorb or reflect EMI. Ferrite beads are integrated into cables to suppress high-frequency noise, ensuring stable communication across protocols like CAN bus or Modbus.

4. Thermal Management Materials

Heat dissipation is vital for preventing component degradation. Ceramic substrates or aluminum nitride (AlN) are used for high-power transceiver circuits due to their excellent thermal conductivity. Thermal interface materials (TIMs), such as silicone pads or graphite sheets, bridge heat-generating components and heat sinks to maintain optimal operating temperatures.

5. Durable Connectors and Housing

High-performance plastics like PBT (polybutylene terephthalate) or PA66 (nylon) form connector housings, offering resistance to chemicals, UV exposure, and abrasion. Gold-plated pins in connectors ensure corrosion-free contacts, maintaining signal clarity over prolonged use.

Why Material Selection Matters

Superior materials enhance the module’s resilience against environmental challenges while ensuring seamless communication between the BMS and external systems like chargers or vehicle ECUs. For instance, robust EMI shielding prevents data corruption during high-current operations, and advanced thermal materials mitigate overheating risks in compact battery compartments.

Conclusion

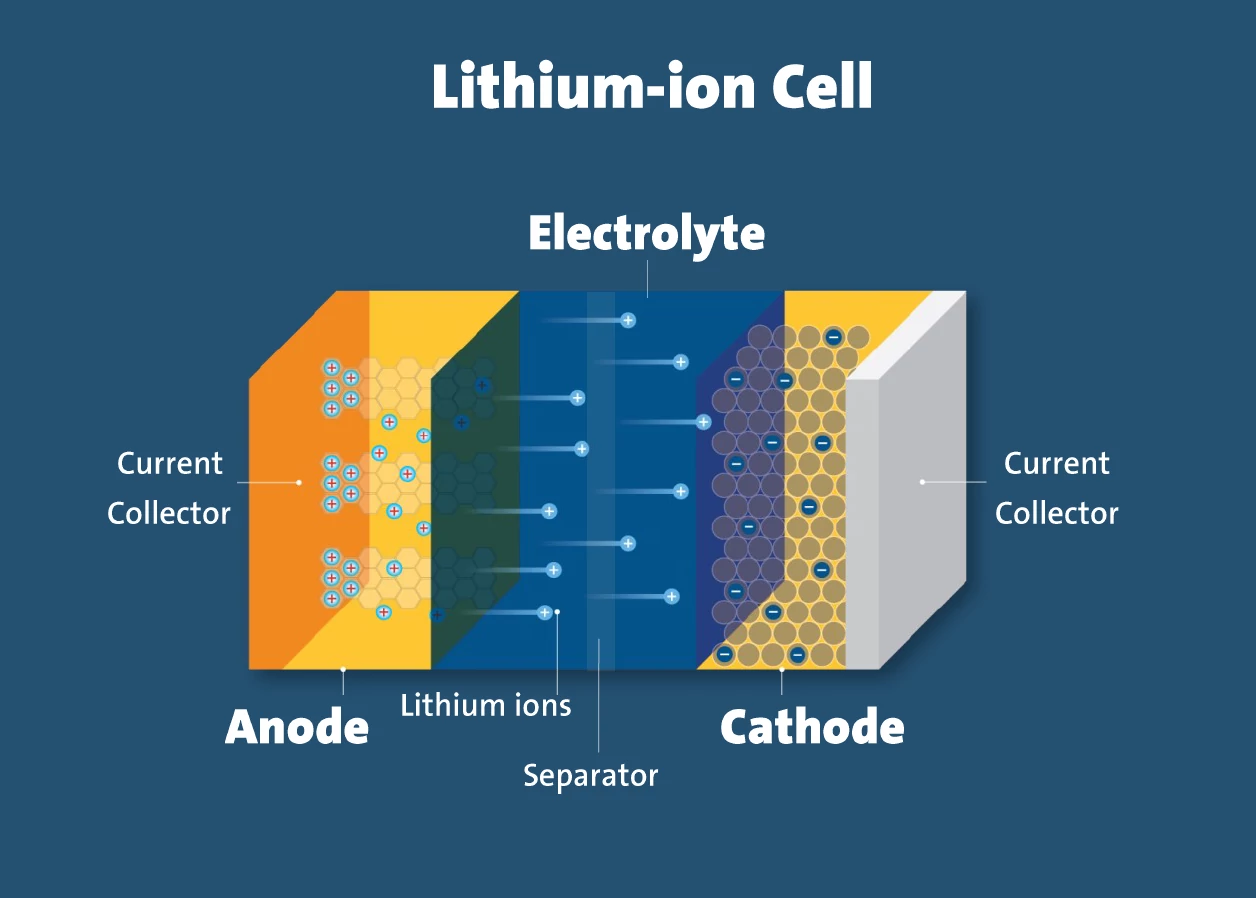

The BMS communication interface module materials for motorcycle batteries are engineered to balance electrical efficiency, mechanical strength, and environmental adaptability. By leveraging high-grade conductive alloys, advanced polymers, and specialized shielding solutions, these modules deliver unmatched reliability for modern lithium-powered motorcycles.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!