TwinScrew Continuous Slurry Preparation: Revolutionizing Battery Material Manufacturing

main content

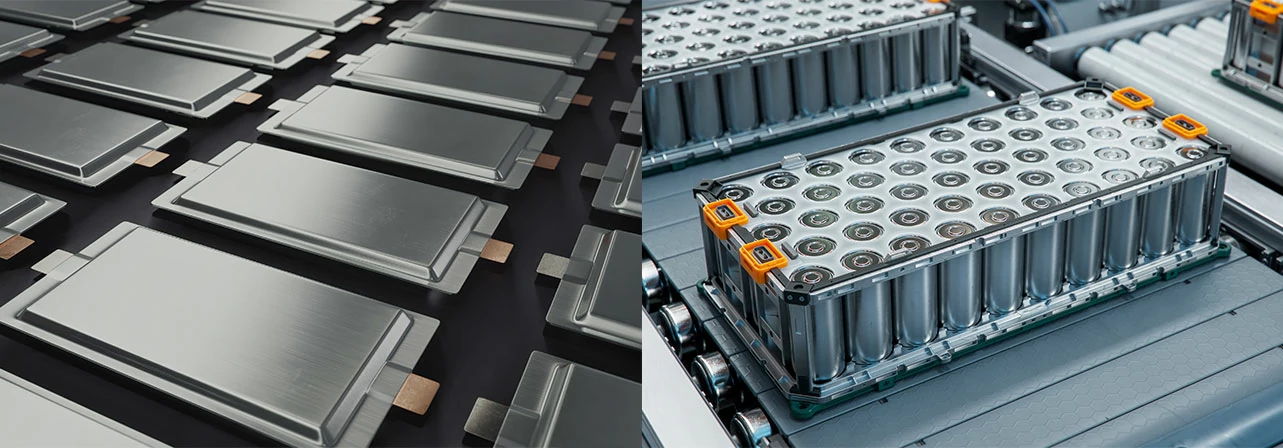

Twinscrew continuous slurry preparation is an advanced method for producing battery materials with unmatched efficiency and consistency. This technology leverages a twinscrew extruder to enable continuous production, minimizing batch variability while optimizing output. Ideal for modern battery manufacturing, it integrates conductive agent pretreatment, precision material mixing, and viscosity reduction to deliver highquality slurries.

How It Works

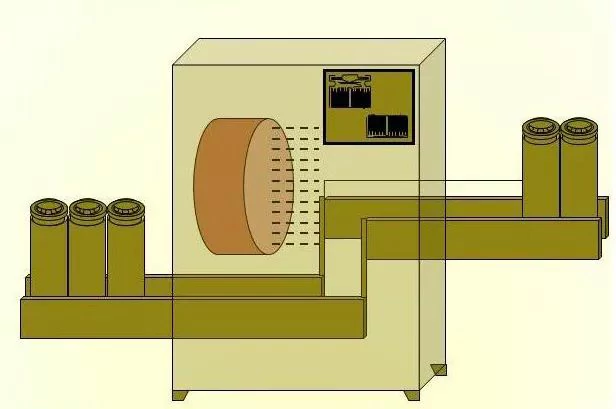

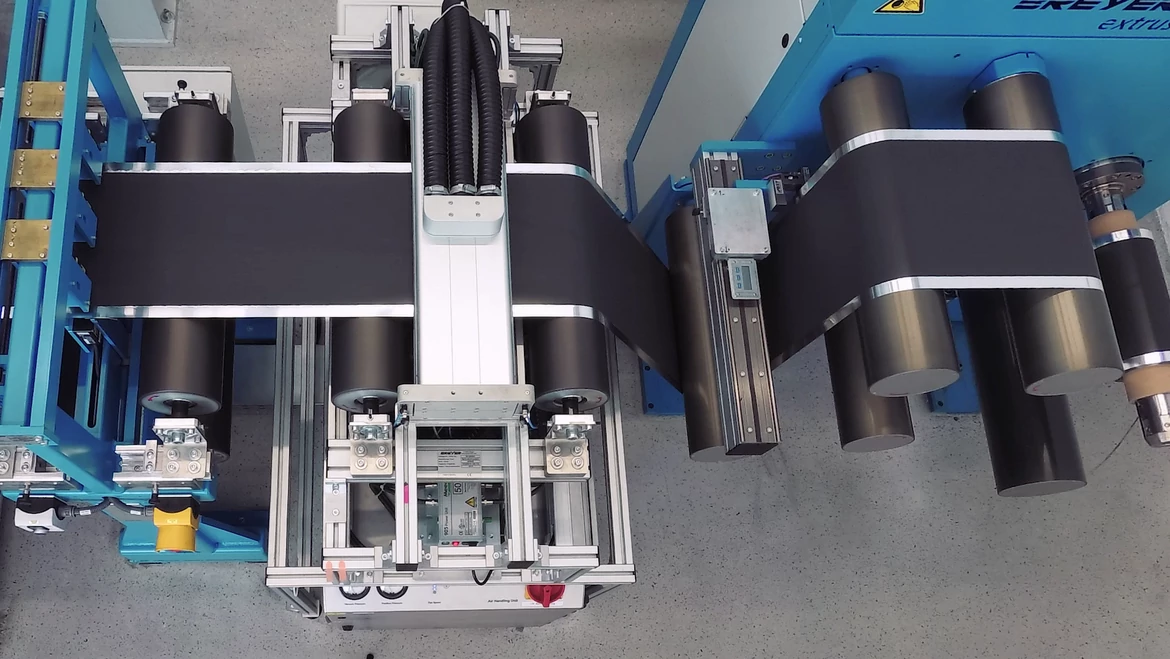

The process begins by premixing the conductive agent into a colloidal solution. This solution, along with active materials and solvents, is fed into the twinscrew extruder at precisely controlled flow rates. Inside the extruder, high shear forces ensure uniform dispersion. The mixture then passes through a highspeed disperser, which reduces viscosity for smoother downstream processing.

Key Advantages

1. Enhanced Productivity: Continuous operation eliminates downtime between batches, boosting output by up to 50% compared to traditional methods.

2. Superior Consistency: Realtime monitoring and automated controls maintain strict ratios, ensuring identical slurry properties across batches.

3. Reduced Waste: Precise material dosing minimizes excess raw material usage.

Challenges to Consider

While highly efficient, twinscrew systems face significant wear due to abrasive materials. Regular maintenance, including screw replacement and lubrication, is critical to avoid unplanned downtime. Additionally, the initial investment in specialized equipment may be higher than batchbased alternatives.

Optimizing Performance

To maximize ROI, manufacturers should prioritize wearresistant screw designs and predictive maintenance schedules. Combining this technology with inline quality checks further ensures stable slurry quality while lowering longterm operational costs.

Conclusion

Twinscrew continuous slurry preparation offers a transformative solution for scalable, highquality battery material production. By balancing cuttingedge efficiency with proactive maintenance strategies, manufacturers can achieve both cost savings and competitive product performance.

RELATED BLOG

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!