Lithium Battery Electrode Coating Process: A Comprehensive Guide

main content

Lithium battery electrode coating is the cornerstone of highperformance battery manufacturing, ensuring uniform active material distribution and structural integrity. This sixstage process combines mechanical precision and thermal management to produce defectfree electrodes. Below, we break down each critical phase and its role in achieving optimal electrochemical performance.

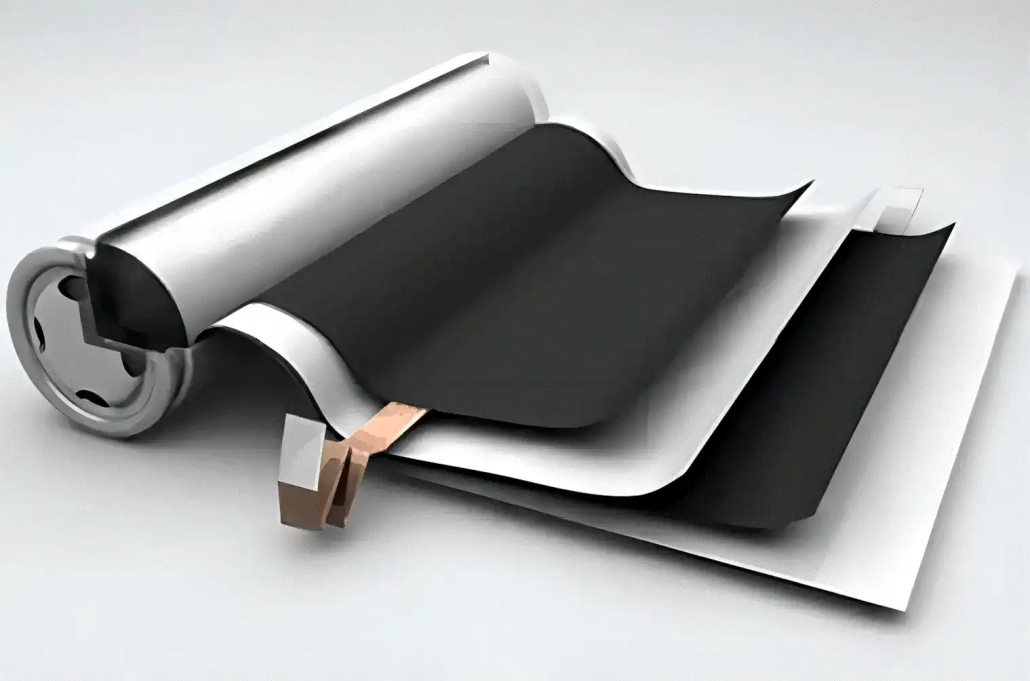

Stage 1: Unwinding – Stability at the Starting Line

The process begins with unwinding aluminum or copper foil from large rolls. Tension control systems maintain consistent foil movement, preventing wrinkles or breaks. Advanced sensors adjust tension dynamically, compensating for speed fluctuations up to 100 m/min. Cleanroomgrade handling minimizes particulate contamination during this phase.

Stage 2: Splicing – Seamless Continuity

Automatic splicing units weld foil ends using ultrasonic or thermal methods, ensuring uninterrupted production. Laser alignment tools verify overlap accuracy (±0.05 mm), while adhesivefree joints prevent coating defects. This step is vital for 24/7 manufacturing cycles, reducing downtime by 90% compared to manual splicing.

Stage 3: Tension & Alignment – Precision in Motion

Realtime tension sensors and servodriven rollers maintain 10–30 N/m² tension across the foil. Simultaneously, CCD cameras scan edge positions, triggering pneumatic actuators to correct deviations within ±0.1 mm. Closedloop feedback systems update adjustments every 0.2 seconds, adapting to speed changes from 5 m/min to 80 m/min.

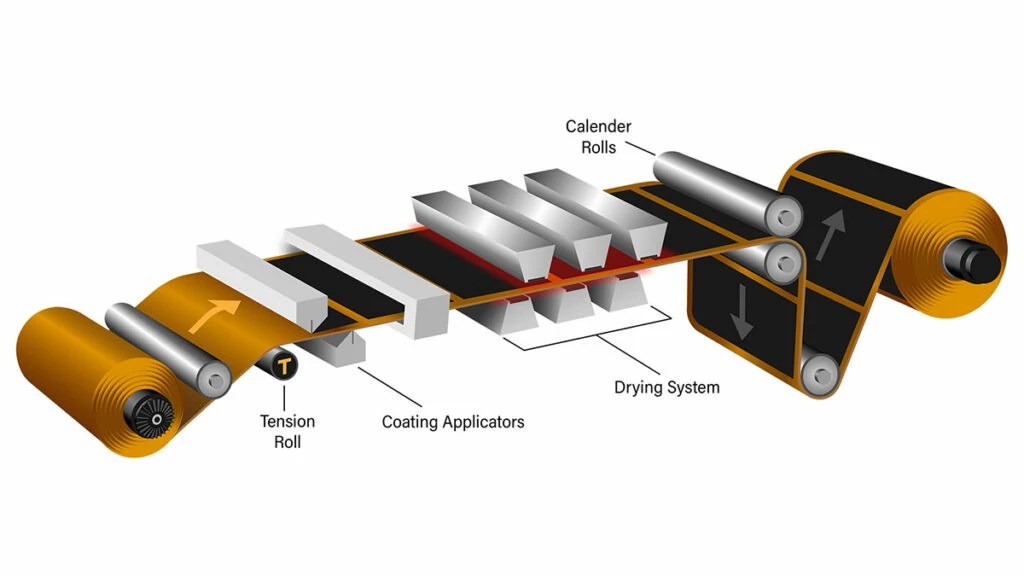

Stage 4: Coating – The Art of Uniformity

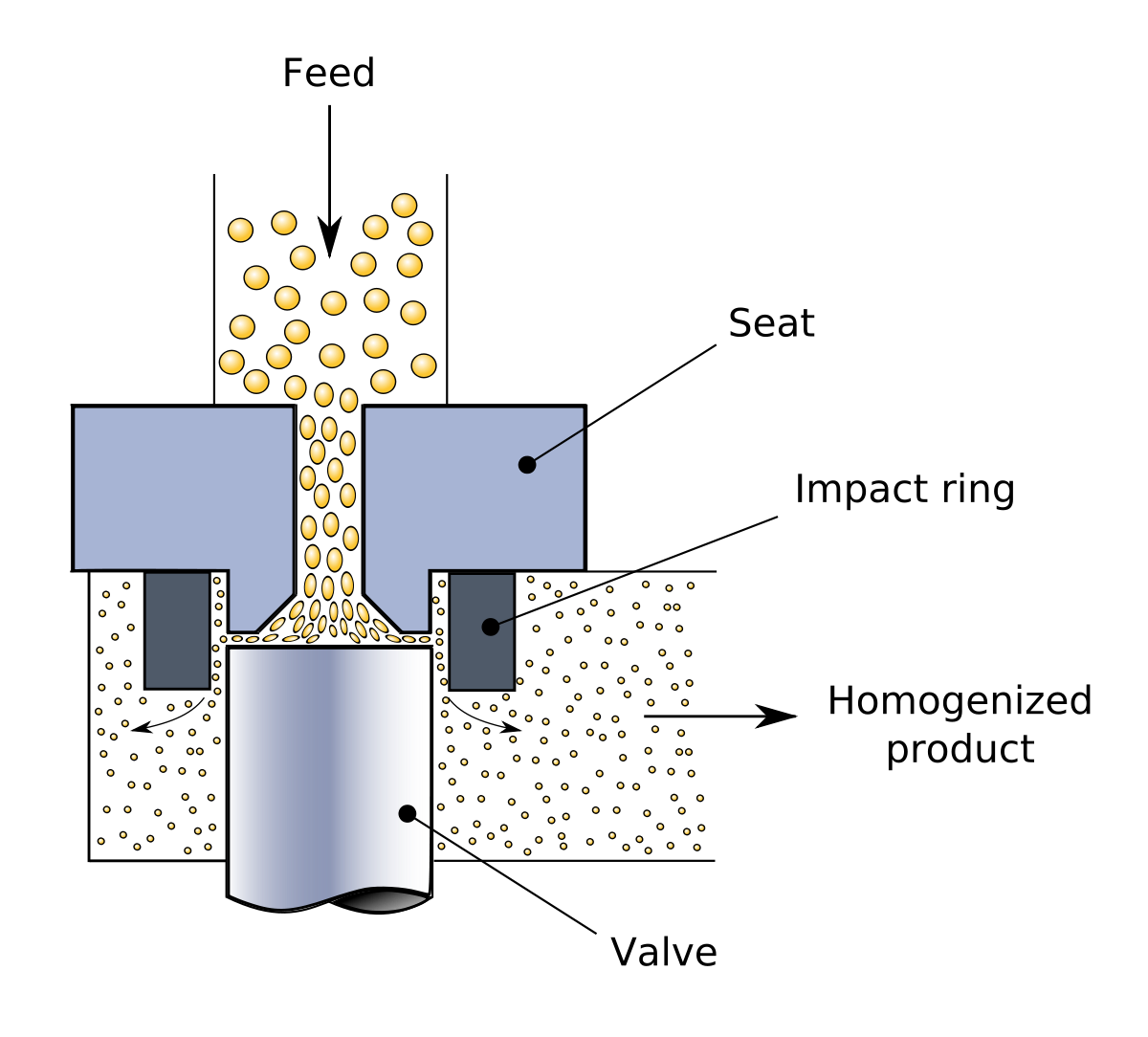

Two dominant methods ensure precise slurry application:

1. Transfer Coating: A rotating roller meters slurry through a doctor blade gap (20–200 μm adjustable), ideal for lowviscosity slurries (<5,000 mPa·s).

2. SlotDie Coating: Pressurized slurry (0.1–0.5 MPa) extrudes through a precision die, forming 50–300 μm layers with ±2% thickness variation. This method excels for highviscosity slurries (>10,000 mPa·s) and multilayer coatings.

Stage 5: Drying – Balancing Speed & Quality

Multizone ovens apply gradient heating (60°C → 85°C) to remove NMP or water solvents. Airflow velocity (1–3 m/s) and humidity (<10% RH) are tightly controlled to prevent binder migration or cracking. Infrared sensors monitor solvent content, adjusting dwell times from 2–10 minutes based on coating thickness.

Stage 6: Winding – Preparing for Next Steps

Tensioncontrolled turrets wind dried electrodes into 500–1,500 mm diameter rolls. Antistatic ionizers eliminate charge buildup (>99% discharge efficiency), while edgeguiding systems maintain ±1 mm alignment for downstream slitting and calendering.

Conclusion: Synergy for Superior Electrodes

Modern coating lines integrate these stages with AIdriven predictive maintenance, achieving <0.5% defect rates. By optimizing tension control, alignment accuracy, and thermal profiles, manufacturers boost energy density by 15–20% while cutting solvent usage by 30%. As solidstate batteries evolve, advanced coating technologies will remain pivotal in scaling up nextgen energy storage solutions.

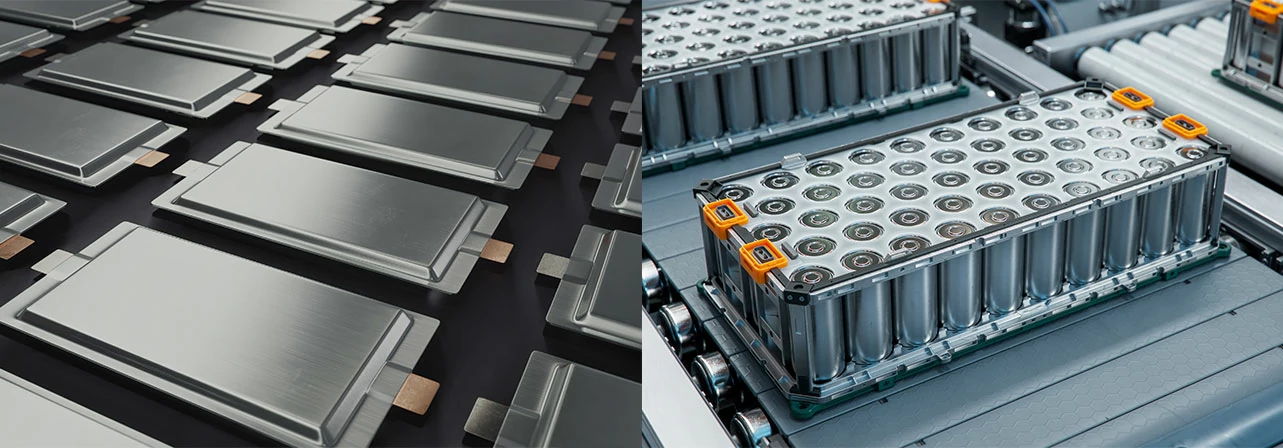

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!