Dry homogenization process for Cathode of Lithium-ion Batteries

main content

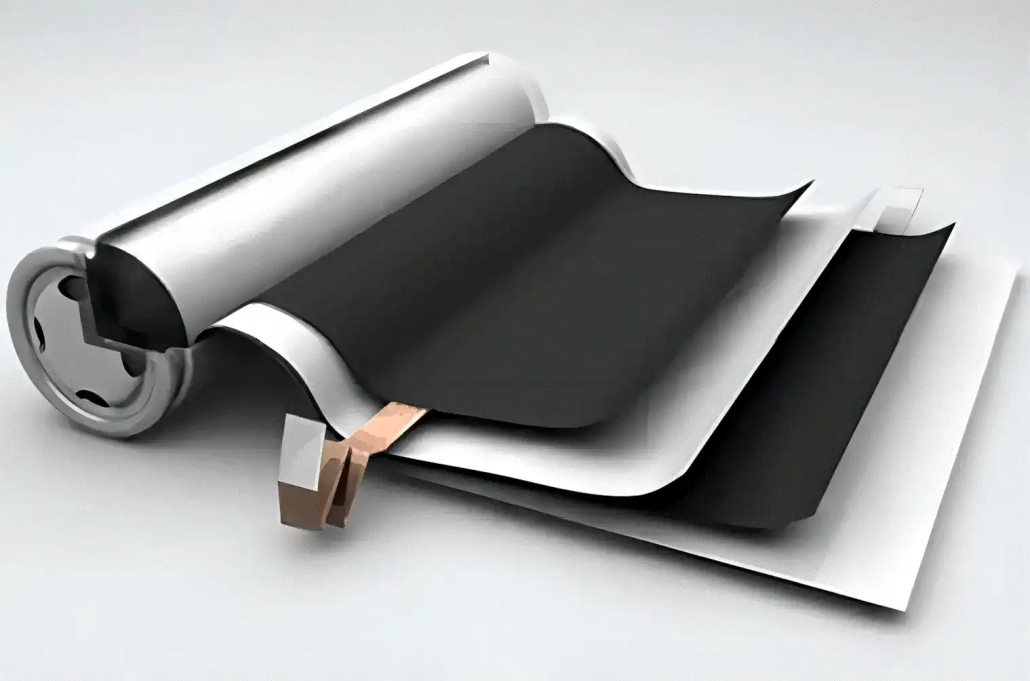

Dry homogenization process, as an important innovative direction in the manufacturing of lithium-ion battery electrodes, is characterized by "gel-free liquid preparation", and achieves the preparation of high-solid-content slurry through powder premix and gradient dispersion. This process is particularly suitable for the demands of high energy density batteries, but it faces severe challenges in controlling the uniformity of material dispersion. The following analysis will be conducted from the aspects of process principles, technical advantages and core difficulties.

I. Principles and Core Processes of Dry Process

1. Process design concept

The dry process breaks through the traditional wet process of "making glue first and then dispersing", and adopts a three-stage innovative path of "dry-mixing wet-dispersion". The core lies in:

Omission in the preparation of the adhesive solution: Directly introduce the binder (such as PVDF) in powder form, eliminating the pre-dissolution step of the adhesive solution and shortening the process cycle by 30% to 50%.

Solvent usage optimization: NMP (N-methylpyrrolidone) is added through staged spray, reducing the total solvent usage by 20% to 30% compared to the wet method.

2. Process steps and parameter control

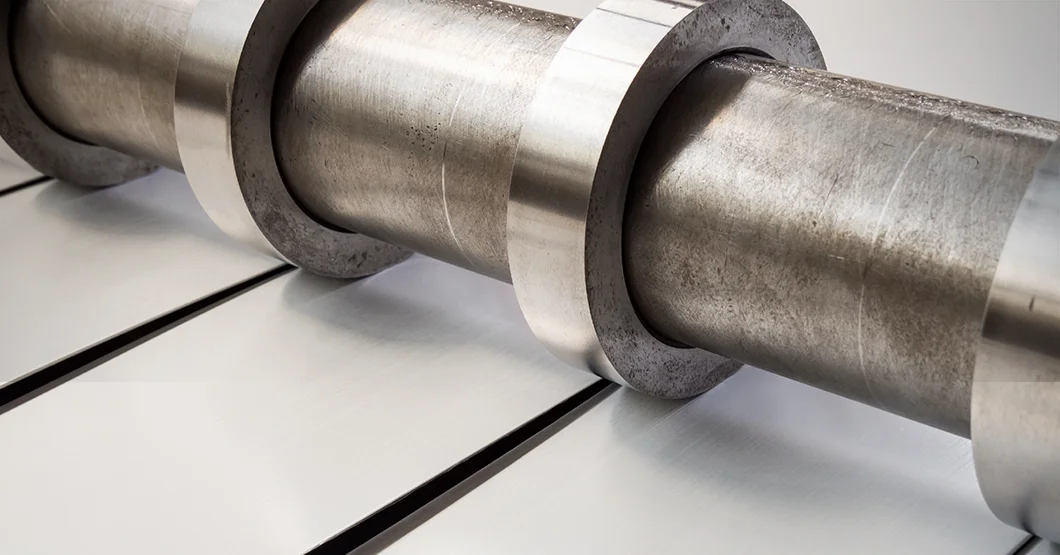

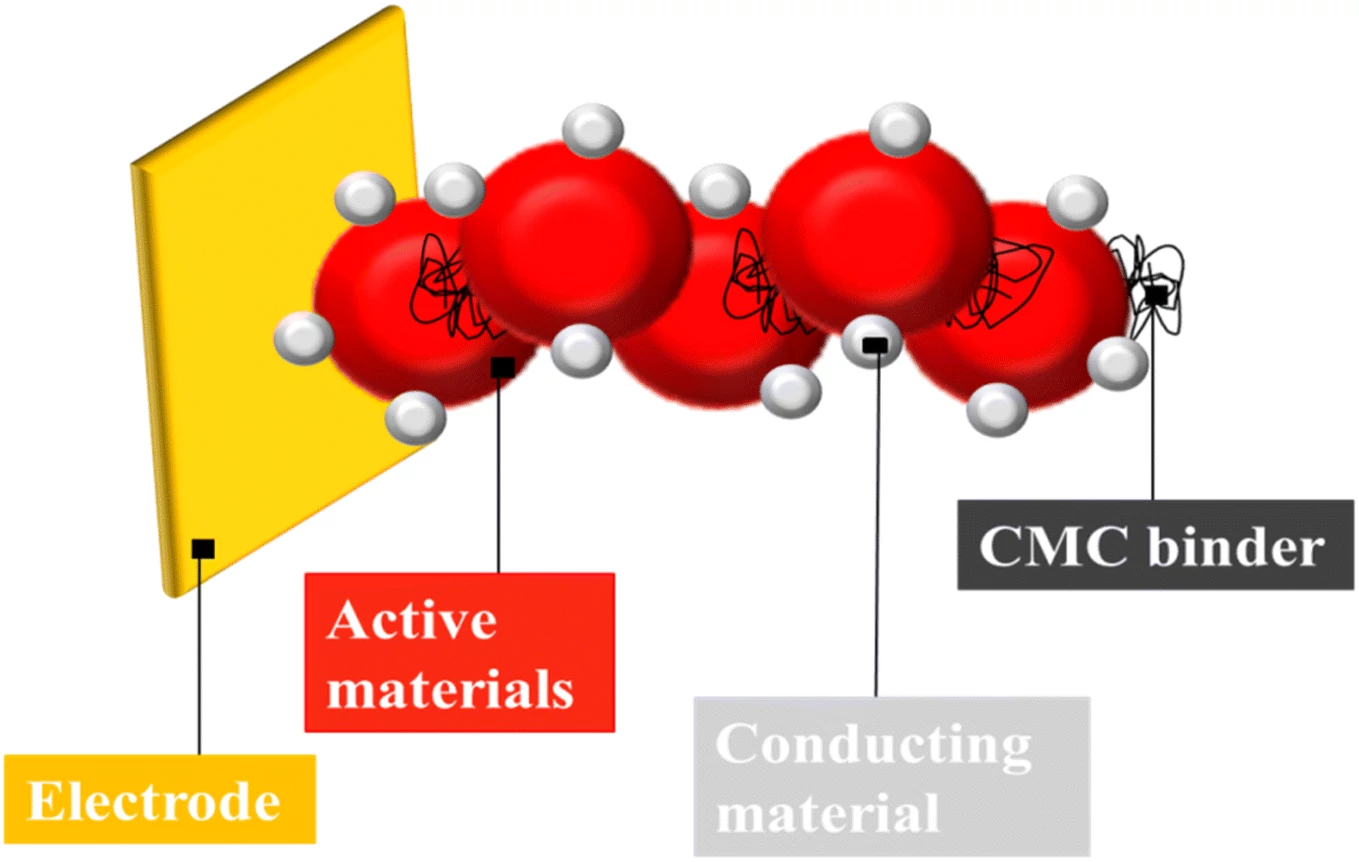

Dry powder premixing stage: The main material of the positive electrode (such as LFP or NCM), conductive agent (SP/CNT) and binder (PVDF powder) are added to the double planetary mixer in proportion, with an orbital speed of 515 r/min and a rotational speed of 400±50 r/min. The premixing time is 3060 minutes, and the target D50 is ≤10 μm. At this stage, the humidity (dew point < 40℃) must be strictly controlled to prevent the PVDF from absorbing moisture and forming lumps.

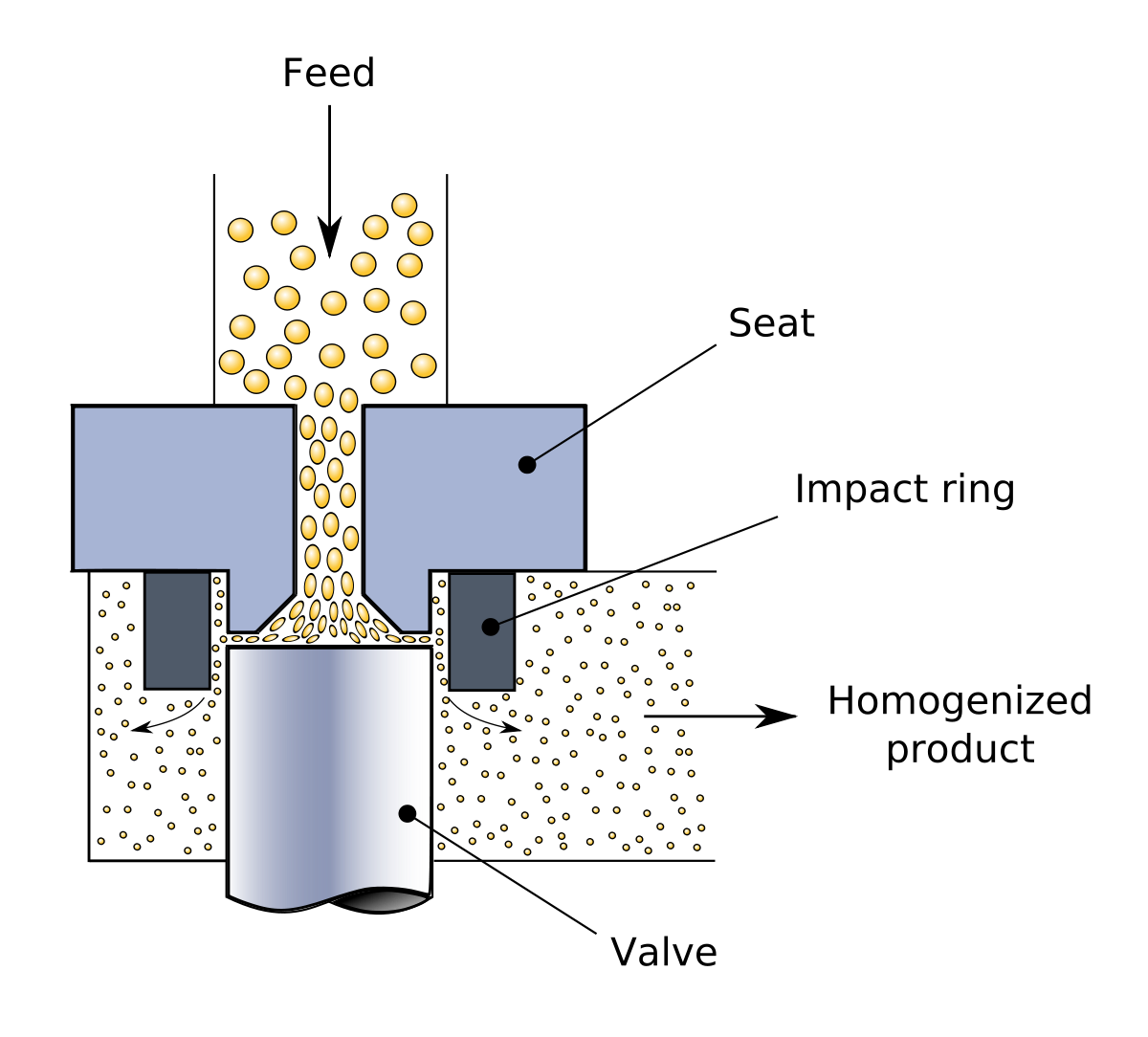

Solvent spray wetting: NMP is sprayed in two phases. The first addition accounts for 40% to 60% of the total solvent, increasing the solid content to 68% to 72%, forming a high-viscosity slurry-like slurry. At this stage, a combination of low-speed revolution (1525 r/min) and intermittent rotation (15200 r/min) is adopted to ensure that the powder is fully wetted.

High-speed dispersion and viscosity reduction: The rotational speed is gradually increased to 1200 to 1500 r/min, combined with vacuum deaeration (≤85 kPa), and the final solid content is adjusted to 5362%, with the viscosity stabilized at 4000 to 8000 mPa·s.

Ii. Technical Advantages and Applicable Scenarios

1. Efficiency and cost advantages

The process cycle is shortened: The total time consumption is compressed from 810 hours in the wet process to 46 hours, and energy consumption is reduced by 30%.

Solvent recovery pressure is alleviated: The usage of NMP is reduced to 0.5 to 0.8 tons per ton of slurry, the scale of the supporting recovery system is shrunk, and the equipment investment cost drops by 25%.

Solid content improvement: The solid content of the slurry can reach 72%, the compaction density of the electrode sheet is enhanced (LFP increases from 2.3g /cm³ to 2.8g /cm³), and the energy density is increased by 10% to 15%.

2. Material compatibility

Advantages of LFP material: It is suitable for the characteristics of large LFP particles (D50=13 μm) and low specific surface area (35 m²/g), and dry mixing can be used to construct a stable conductive network.

Limitations of high-nickel ternary materials: High-activity materials such as NCM are sensitive to moisture (dew point requirement < 40℃), and dry mixing is prone to introducing impurities. Therefore, the wet method is still the main approach.

Iii. Core Challenges and Optimization Strategies

1. The problem of uniformity in powder premixing

Material physical property differences: The density and particle size of the conductive agent (SP specific surface area 6080 m²/g) and the main material (LFP density 2.22.4 g/cm³) are significantly different, which can easily lead to delamination and the "dry island effect".

Agglomeration risk: Undispersed PVDF powder forms "hard agglomeration" during the high shear stage, resulting in a 20% to 30% increase in electrode sheet resistance.

2. Process optimization path

Equipment upgrade: Ceramic-coated blades and ultrasonic assistance (2040 kHz) are adopted to reduce the risk of metal contamination and enhance the dispersion efficiency.

Stepwise feeding strategy: Patent CN110600671B proposes "phased addition of binder". For the first time, 50% PVDF powder is pre-mixed, and then combined with solvent gradient dilution, the dispersion uniformity is improved by 25%.

Online monitoring technology: Introduce a rheometer to monitor the thixotropic recovery time of the slurry in real time (target < 30 minutes), and combine AI to dynamically adjust the rotational speed.

Iv. Future Development Trends

1. Equipment integration: Develop an integrated "dry-mixed coating" production line, combined with the continuous pulping technology of twin-screw extruders, with the goal of achieving a single-line production capacity of over 5,000 tons per year;

2. Material system expansion: Compatible with sodium-ion battery cathodes (such as layered oxides) and sulfide all-solid electrolytes, promoting the application of dry methods in the energy storage field;

3. Intelligent upgrade: Based on digital twin technology, a slurry dispersion model is constructed to achieve self-optimization of parameters and reduce energy consumption by 40%.

Conclusion

The dry homogenization process has significantly enhanced the manufacturing efficiency and environmental friendliness of lithium batteries through process innovation. However, its technological maturity is still limited by the control of material dispersion uniformity. In the future, through equipment innovation, intelligent process parameters and the adaptation of new materials, the dry process is expected to achieve large-scale breakthroughs in the field of high-energy-density batteries and become the core technical paradigm for the next-generation lithium battery manufacturing.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!