Analysis of Semi-dry (Kneading Process) Technology for Lithium-ion Battery Cathode

main content

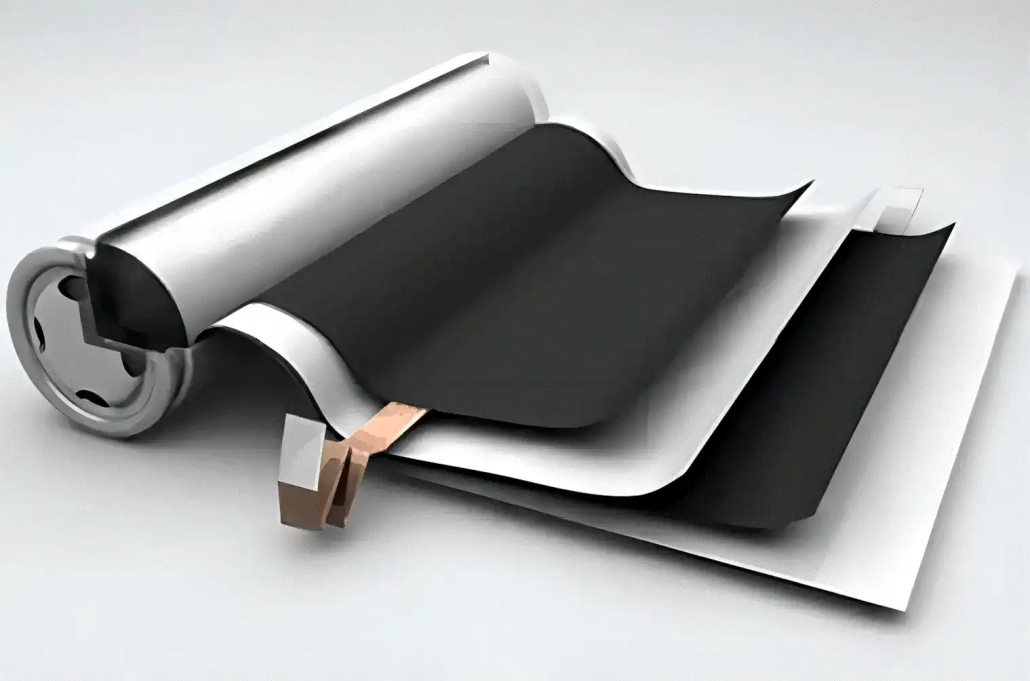

In the manufacturing of lithium-ion batteries, the preparation process of the cathode slurry directly affects the electrode performance and battery life. The traditional wet process requires the pre-preparation of the binder solution, which has bottlenecks such as high energy consumption and long cycle. The semi-dry method (kneading process) achieves efficient dispersion and stable molding of high-solid-content slurries by optimizing the process, and is particularly suitable for materials with high uniformity requirements such as lithium iron phosphate (LFP). The following analysis is conducted from the dimensions of process principles, technical advantages, and applicable scenarios.

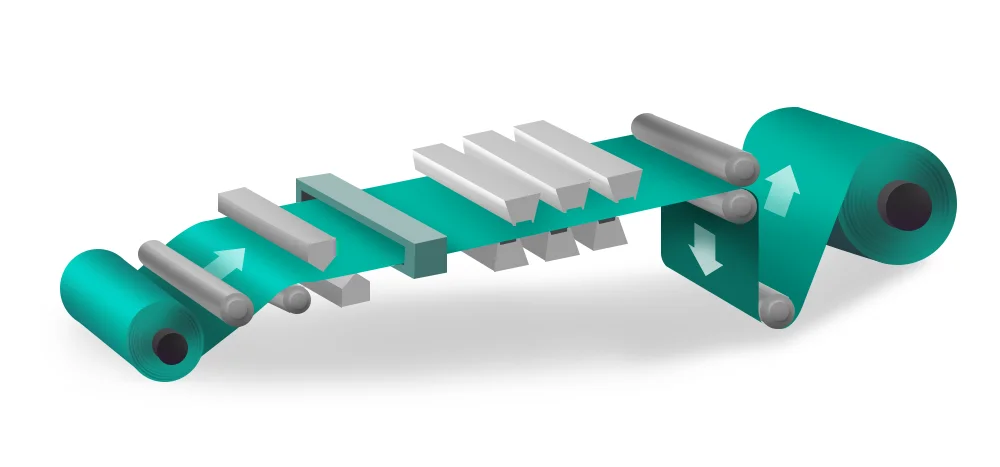

I. Core Flow and Parameter Control of Semi-dry Process

1. Dry powder premixing: Preliminary construction of the conductive network

The semi-dry method omits the step of preparing the adhesive solution and directly dry-mixes the cathode main material (such as LFP), the conductive agent (SP/CNT), and the powdered binder (PVDF). Through the combined effect of the revolution (1530 rpm) and rotation (600-1200 rpm) of the double planetary mixer, the particle agglomeration is broken within 3060 minutes, forming the initial contact network between the conductive agent and the active substance. For instance, patent CN201910995487A indicates that during the dry mixing stage, the humidity should be controlled below 0.5% to prevent PVDF from absorbing water and forming lumps prematurely.

Key technology: A gradient acceleration strategy is adopted. In the initial stage, a low rotational speed (5 rpm per revolution) is used to reduce dust, and it is gradually increased to 1000 rpm per revolution to achieve hard agglomeration and crushing. The D50 can be reduced to below 10 μm.

2. Staged wetting and kneading: Formation of high-viscosity slurry

On the basis of dry mixing, NMP solvent was added in two portions. The first addition accounted for 4060% of the total solvent volume, increasing the solid content to 6872%. At this stage, the kneading mode is activated. The orbital speed is controlled at 25±5 rpm, and the rotation is paused to protect the equipment. This lasts for 3040 minutes. At this time, the slurry presents an influid mud-like structure, and the viscosity can reach more than 20,000 mPa·s.

Microscopic mechanism: Through the strong shearing force between the twisted paddle of the double planetary mixer and the container wall, a uniform PVDFCB coating layer is formed on the surface of the active substance. Studies show that when the absolute value of the Zeta potential of the slurry is greater than 30 mV, the electrostatic repulsion between particles can effectively inhibit sedimentation.

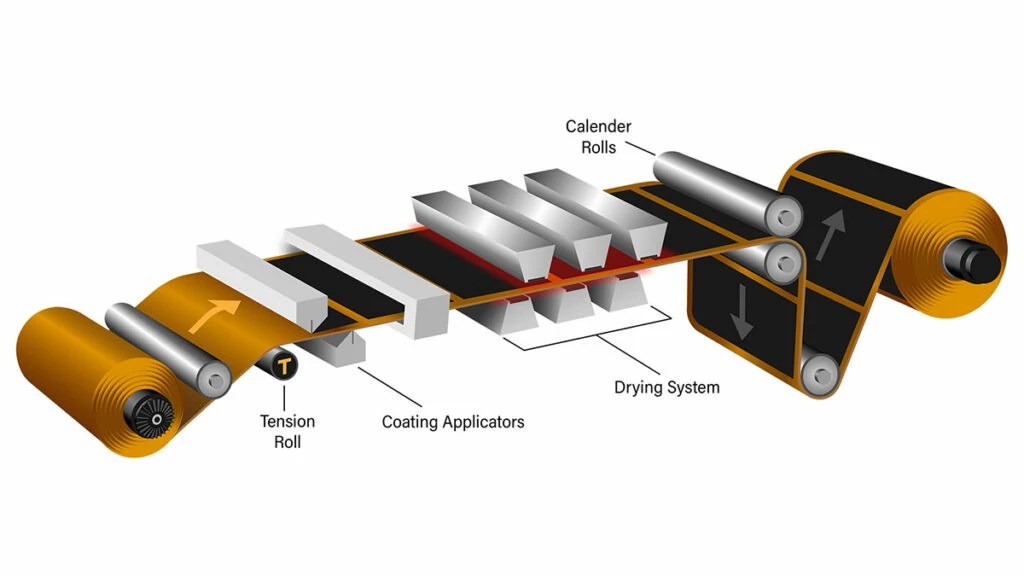

3. Gradient dilution and high-speed dispersion: Precise viscosity control

After the kneading is completed, the remaining solvent is added in stages, and a smooth viscosity transition is achieved through stepwise adjustment of the rotational speed.

Initial dilution: The revolution is increased to 30 rpm, the rotation is activated to 1200 rpm, the solid content is reduced to 5862%, and the viscosity is reduced to 12,000 mPa·s;

Secondary dispersion: Maintain the revolution at 30 rpm, increase the rotation to 1800 rpm, and combine vacuum degassing (≤85 kPa). Eventually, the solid content is adjusted to 5359%, and the viscosity is stabilized at 40006500 mPa·s.

Case: Sunwoda's optimized process shows that at this stage, the TSI (Instability Index) has dropped from 1.05 in the traditional process to 0.75, and the electrode sheet resistance has decreased by 40%.

Ii. Analysis of Technical Advantages and Applicable Scenarios

1. Core advantage

Efficiency improvement: The preparation step of the glue solution is omitted. The total process time is shortened from 8 hours in the wet method to 5 hours, and energy consumption is reduced by 30%.

Dispersion uniformity: Through the physical dispersion mechanism of dry-mixing kneading, the conductive agent and LFP form a three-dimensional interwoven network. The porosity of the electrode sheet is stabilized at 30-40%, and the capacity retention rate is > 90% after 500 cycles.

Environmental optimization: Solvent usage is reduced by 20%, and the energy consumption for NMP recovery is lowered to 0.8 kWh/kg of slurry, meeting the requirements of the EU REACH regulation.

2. Applicable material characteristics

LFP adaptability: LFP particles have a large particle size (D50=13 μm) and a low specific surface area (35 m²/g), making it suitable for dry premixing to construct a stable conductive network.

Limitations of high-nickel materials: High-activity materials such as NCM are sensitive to moisture (dew point requirement < 40℃), and dry mixing is prone to introducing impurities. Currently, the wet method is still the main approach.

3. Process window control

Solid content range: During the kneading stage, it must be strictly controlled at 6872%. If it is too high, it will cause equipment overload (current overload risk > 50%), and if it is too low, it will weaken the shearing and dispersion effect.

Temperature management: An external ring-shaped heater is installed in the second mixing chamber (oil bath temperature 5060℃) to enhance the fluidity of the slurry and prevent local overheating that could lead to the degradation of PVDF (molecular chain breakage at temperatures above 80℃).

Iii. Technical Challenges and Optimization Directions

1. Equipment bottleneck

Power demand: The instantaneous power in the kneading stage reaches 150200 kW/m³. Traditional equipment needs to upgrade to ceramic-coated paddles, reducing the wear rate by 70%.

Large-scale challenge: The twin-screw continuous equipment still has the risk of metal debris contamination and needs to be combined with ultrasonic dispersion (2040 kHz) to improve the premiking efficiency.

2. Material modification

Binder innovation: The development of lithiated PVDF (LiPVDF) has increased the ionic conductivity by three times and reduced the amount of conductive agent by 10%.

Solvent substitution: In the test water-alcohol complex system (with isopropyl alcohol accounting for 5%), the surface tension decreased from 72 mN/m to 35 mN/m, and the wetting time was shortened by 50%.

3. Intelligent upgrade

Online monitoring: A rheometer is used to provide real-time feedback on the thixotropic recovery time of the slurry (target < 30 min), and AI is combined to dynamically adjust the rotational speed and feeding rate.

Digital twin: By using simulation models to predict the particle size distribution of slurry, optimize process parameters, and increase batch consistency to 98%.

Iv. Future Development Trends

1. Equipment integration: Develop an integrated kneading and coating production line, with the goal of achieving a single-line production capacity of over 5,000 tons per year and a coating surface density fluctuation of less than ±1.5%.

2. Breakthrough in high solid content: Through the dry-wet mixing process (premixed solid content 80%), the total solid content is increased to 75%, and the drying energy consumption is reduced by 20%.

3. Material system expansion: Compatible with cathode materials for sodium-ion batteries (such as layered oxides), promoting the application of kneading processes in the energy storage field.

Conclusion

The positive semi-dry method (kneading process) provides an efficient and uniform solution for high-solid-content systems such as LFP through a three-stage innovation of dry-mixing, kneading and dispersion. Despite the challenges of equipment wear and scalability, with breakthroughs in material modification and intelligent control, this process is expected to become the core technology for the manufacturing of the next generation of high-energy-density batteries, driving the lithium battery industry towards a more environmentally friendly and low-cost direction.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!