The core functions of BMS

main content

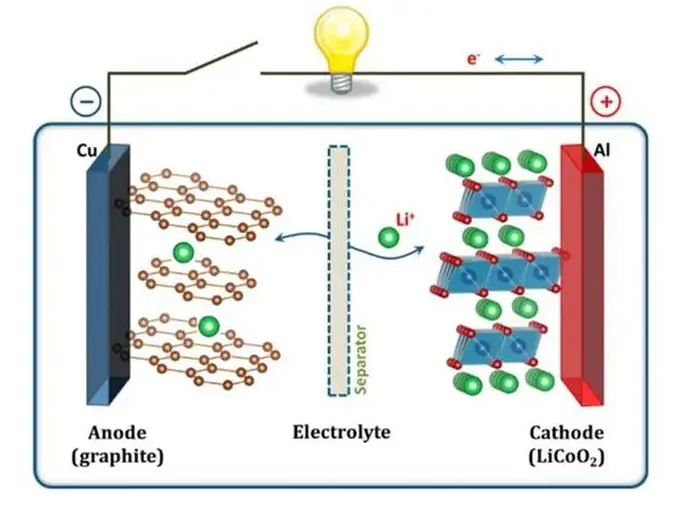

With the rapid development of the electric motorcycle market, lithium batteries have gradually become the mainstream power source due to their advantages such as high energy density and lightweight. However, the chemical properties of lithium batteries pose safety risks in scenarios such as overcharging, overdischarging, high temperatures or vibration. Therefore, the battery management system (BMS) has become a key technology to ensure the safety and performance of lithium batteries. The BMS for starting a motorcycle lithium battery, through real-time monitoring, intelligent protection and efficient communication, realizes the full life cycle management of the battery and serves as the "smart brain" of the power system. This article will conduct an analysis from four core functions: real-time monitoring, security protection, charge and discharge management, and data communication.

Real-time Monitoring and Data Collection

Multi-dimensional parameter monitoring

BMS collects the following key parameters in real time through high-precision sensors and application-specific integrated circuits (such as ADI LTC6811, TI BQ series chips) :

Voltage monitoring: Detect the voltage of each battery cell with an accuracy of ±1mV to identify overvoltage (such as ternary lithium ≥4.25V) or undervoltage (such as lithium iron phosphate ≤2.5V) states of individual cells, preventing capacity imbalance.

Current detection: Hall sensors or shunt resistors are used to dynamically track the charging and discharging current (for example, when the instantaneous current reaches over 10C during the cold start of a motorcycle), preventing overcurrent from causing thermal runaway.

Temperature perception: The surface temperature of the battery cells is monitored at multiple points through NTC thermistors or digital sensors (with a typical error of ±1℃) to ensure safety threshold control at high temperatures (≥45℃) or low temperatures (≤-20℃).

Data processing and state estimation

The BMS integrated algorithm (such as the Ampere-hour integration method + open-circuit voltage method) calculates the core state of the battery:

SOC (State of Charge) : Estimates the remaining battery power with an accuracy of ±3%, providing a basis for range prediction.

SOH (Health Status) : The battery life is evaluated by the rate of capacity decline and the change in internal resistance. A maintenance warning is triggered when SOH is less than 80%.

Security Protection Mechanism

Active and passive protection

Overcharge/overdischarge protection: When the voltage of a single cell exceeds the threshold (such as 4.25V overcharge of ternary lithium), the BMS cuts off the circuit through MOSFET or relay and supports automatic restart after voltage recovery.

Temperature protection: Charging and discharging are prohibited at high temperatures. The preheating module (such as PTC heating film) is activated in a low-temperature environment to ensure cold start performance at -40℃.

Short-circuit and overcurrent protection: Dual protection is achieved through hardware fuses (such as fast-melt fuses) and software delay judgment (typical response time <10ms).

Balanced management

Passive balancing: Dissipates the energy of high-voltage individual cells through resistors (balancing current ≤100mA), suitable for cost-sensitive scenarios.

Active balancing: Utilizing inductors or capacitors to transfer energy (with an efficiency of ≥85%), it is suitable for high-power motorcycle battery packs, reducing the impact of capacity differences on lifespan.

Optimization of Charging and Discharging Management

Dynamic power control

The BMS dynamically adjusts the charging and discharging strategy based on SOC and temperature:

Charging stage: The constant current - constant voltage (CC-CV) mode is adopted, combined with the balancing function to achieve cell consistency (voltage difference ≤30mV).

Discharge stage: Limit the duration of large current pulses (such as 10C rate during cold start) to prevent stress damage to the electrode sheets.

Low-temperature adaptability

Through the optimization of the electrolyte formula (low-viscosity carboxylate ester solvent) and the BMS preheating technology (temperature rise rate ≥10℃/min), it is ensured that the capacity retention rate at -30℃ is > 70%.

Data Communication and System Integration

Multi-protocol communication interface

CAN bus: It meets the requirements of the national standard GB/T 27930-2015 for electric motorcycles and realizes data interaction between the BMS and the vehicle controller as well as the charging pile (such as fault code transmission).

Bluetooth /Wi-Fi: It is used for the user APP to view the battery status (such as SOC, temperature) in real time, and supports remote diagnosis and firmware upgrade.

Information storage and traceability

The built-in memory of the BMS records the number of charge and discharge cycles and fault logs (such as the timestamp of overvoltage events), providing data support for after-sales maintenance.

Conclusion

The BMS for motorcycle starting lithium batteries has significantly enhanced the reliability and service life of the battery system through precise data collection, multi-level safety protection, and intelligent charging and discharging strategies. With technological iteration, in the future, BMS will deeply integrate AI algorithms (such as neural network prediction of SOH) and wireless communication technologies (such as 5G remote monitoring), further breaking through the performance boundaries of lithium batteries under extreme working conditions. From material innovation to system integration, BMS is driving electric motorcycles to evolve towards greater safety and efficiency, becoming an indispensable technological cornerstone in the era of green travel.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!