Terminal connection technology for motorcycle starting lithium batteries

main content

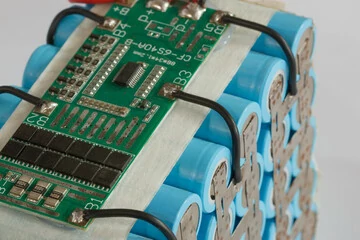

Motorcycle start-up lithium battery is the core component of the power system, and its terminal connection design directly determines the energy transmission efficiency and system reliability. When the instantaneous cold start current is more than 10C, the output power of the battery can be increased by 5%-8% when the contact resistance of the terminal is reduced by 0.1mΩ. The mechanical stress impact in the vibration environment requires the connection structure to have anti-fatigue characteristics. This paper analyzes the technical principle and engineering application of terminal connection from the four dimensions of mechanical connection, crimping technology, welding process and intelligent connection.

Mechanical connection: basic guarantee for screw fixation

Technical characteristics of screw connection

The core advantage of screw connection is that the terminals and wires are fixed by physical locking of metal threads:

Removable: support multiple disassembly and maintenance, suitable for motorcycle battery frequent replacement scenarios (such as Harley LiveWire model maintenance cycle of more than 500 times).

Anti-vibration performance: self-locking nut and spring gasket design, can withstand 15G vibration acceleration, contact pressure fluctuation range ≤5%.

Conductive efficiency: copper alloy screw with silver-plated gasket, the contact resistance is stable at 0.15-0.25mΩ, to meet the demand of 10C rate discharge.

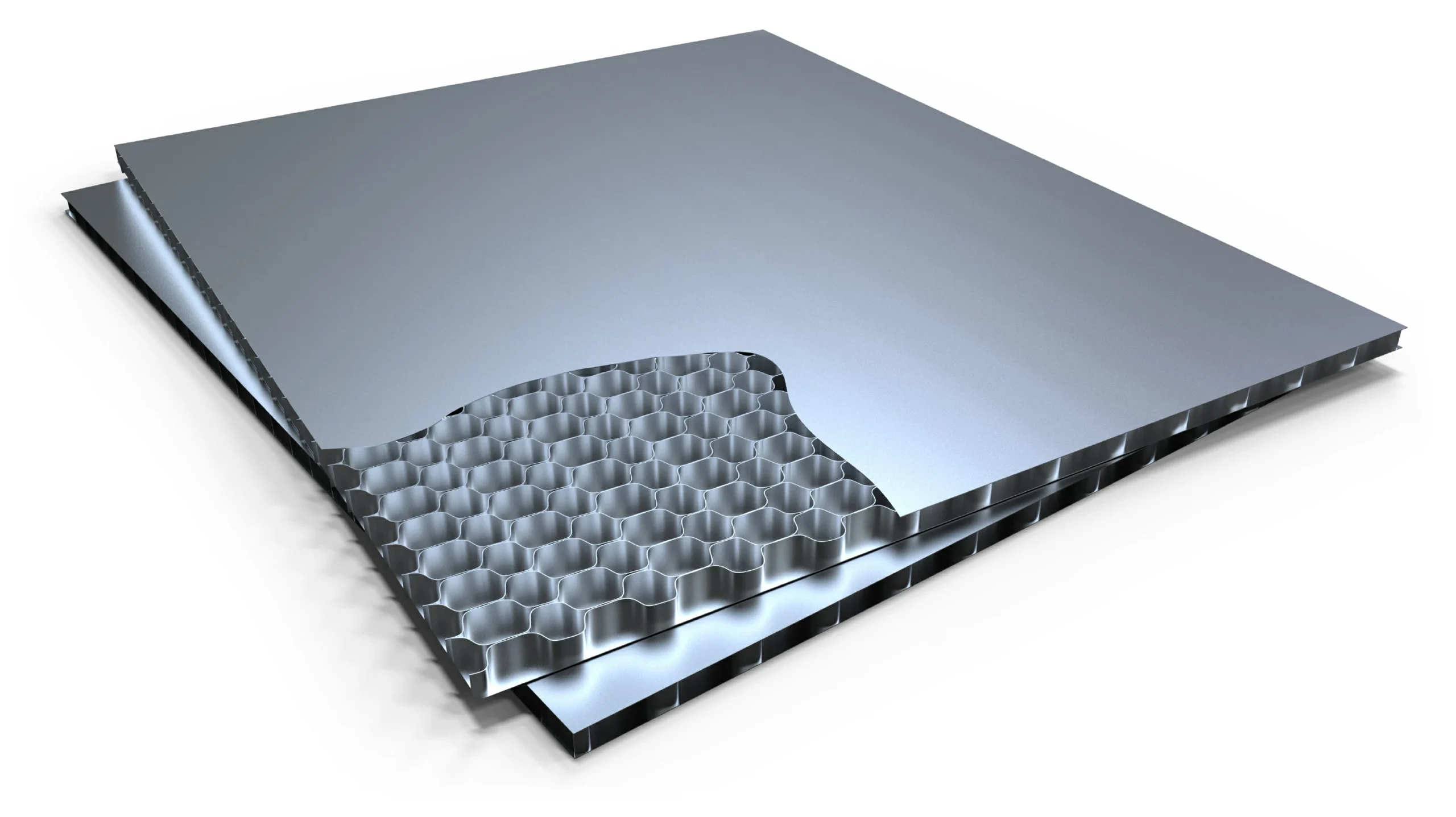

crimping technology: advanced scheme with high reliability

Scientific breakthrough in cold pressing process

Crimping is a metallurgical bond formed by plastic deformation of metals. Its technical characteristics include:

Low impedance characteristics: The use of multi-tooth crimp die, so that the copper terminal and the wire to achieve 360° full circle contact, contact resistance ≤0.08mΩ (60% lower than screw connection).

Environmental adaptability: The corrosion rate of the Hastlet crimped terminal is only 0.002mm/ year in the salt spray test, which is suitable for the coastal high humidity environment.

welding process: the ultimate pursuit of molecular level combination

1. The technical advantages of laser welding

Interface fusion: 1070nm fiber laser is used to realize the metallurgical bonding of copper-aluminum dissimilar metals with shear strength ≥80MPa.

Micro control: welding penetration accuracy ±0.1mm, heat affected zone ≤200μm, avoid thermal damage of lithium-ion battery diaphragm.

2. Challenge and innovation

Defect prevention and control: through plasma online monitoring technology, the porosity is reduced from 3% to less than 0.5%.

Material innovation: The melting point of silver brazing (Ag85-Cu15) is reduced to 650℃, and the welding heat input is reduced by 40%.

Conclusion

From mechanical locking of screw connection to molecular bonding of laser welding, motorcycle lithium battery terminal connection technology is experiencing a leap innovation from macro structure to micro interface. Currently, the crimping process reduces the contact resistance to 0.08mΩ through 8-point synchronous pressure technology, and the intelligent connection system realizes pressure self-compensation through piezoelectric sensing. With the application of cold-pressing and welding composite process (contact resistance ≤0.05mΩ) and topology-optimized materials, future terminal designs will break through the physical limits of conductive efficiency and reliability, providing a more powerful energy transfer hub for high-performance electric motorcycles.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!