Seismic structure optimization - filled with elastic silicone rubber material

main content

The mechanical vibration and shock generated during the operation of motorcycles pose a severe challenge to the stability of the internal structure of lithium batteries. Studies show that when a vehicle is jolted, the acceleration that lithium batteries are subjected to can reach over 15G. Long-term mechanical stress shock can lead to problems such as friction between battery cells, electrode plate breakage, and electrolyte leakage, and even cause the risk of thermal runaway. In recent years, by filling elastic silicone materials in the gaps of battery cells and optimizing the design through structural mechanics, the anti-vibration performance of lithium batteries has achieved a breakthrough improvement. Experimental data show that the elastic silicone rubber buffer structure can reduce mechanical stress shock by 30% and extend the cycle life by more than 50%.

The damage mechanism of mechanical vibration to lithium batteries

Microcrack propagation in electrode materials

High-frequency vibration causes repeated collisions between the active material particles of the positive and negative electrodes. When the stress fluctuation between the layers of the graphite negative electrode exceeds 0.5MPa, micron-sized cracks will form, blocking the lithium-ion intercalation channels and increasing the capacity attenuation rate by 3 to 5 times.

The risk of diaphragm perforation has increased

When polyolefin diaphragms are subjected to shear force in a vibrating environment and the local strain exceeds 4%, the pore structure undergoes irreversible deformation, increasing the probability of micro-short circuits to eight times that of normal working conditions.

Imbalance in the distribution of the electrolyte

Under the action of centrifugal force, the electrolyte accumulates towards the edge of the battery cell, and the "drying up" phenomenon occurs in the central area, resulting in the interface impedance surging from 50mΩ·cm² to 200mΩ·cm² and the polarization voltage increasing by 0.3V.

The principle of elastic silicone rubber buffering technology

Innovation in material properties

Super soft silicone foam: Made of three-dimensional network structure silicone material with 85% porosity (Shore hardness 10HA), its compression and rebound rate is ≥95%, and it can absorb the displacement of 0.3-0.5mm caused by the expansion of battery cells.

Gradient modulus design: The outer layer uses high-elastic silicone gel (with an elastic modulus of 0.05MPa) to absorb high-frequency vibrations, while the inner layer adopts high-damping silicone gel (with a loss factor of 0.8) to dissipate low-frequency impact energy, achieving wideband vibration attenuation.

Structural engineering design

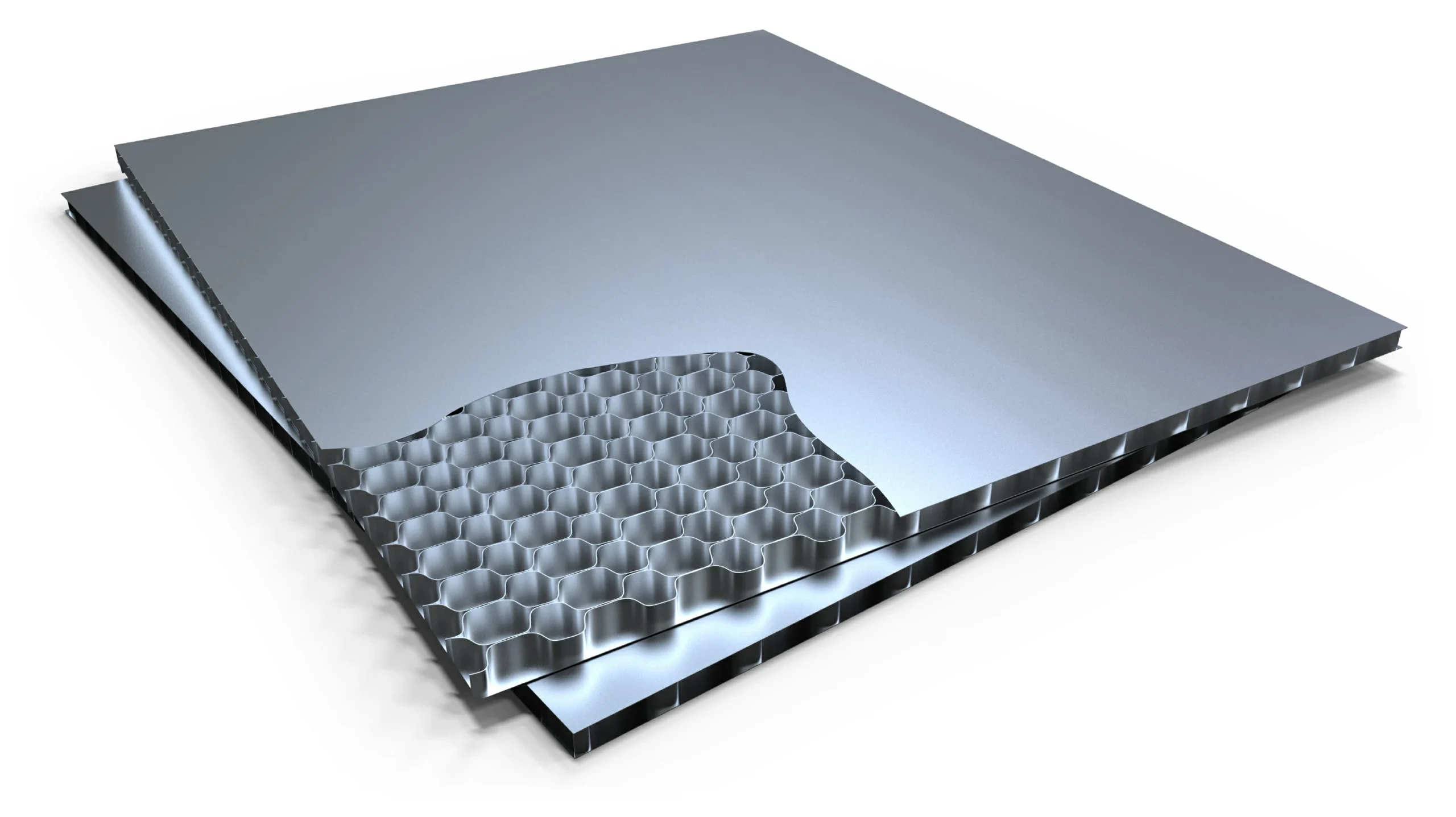

Honeycomb filling layout: A 2mm thick silicone buffer layer is constructed in the battery cell gap, and the local pressure is dispersed from 3.2MPa to 0.7MPa through the hexagonal honeycomb structure.

Snake-shaped channel heat dissipation integration: By embedding graphene heat conduction channels in the silicone matrix, the heat transfer efficiency is increased by 40%, and the temperature rise rate is controlled at 1.2℃/min (under 10C discharge conditions).

Optimization of mechanical properties

Dynamic stress matching: The ratio of the energy storage modulus (G') to the loss modulus (G ") of the silicone material is designed at 1:0.6, which can simultaneously cope with mechanical shocks in the vibration frequency band of 20-2000Hz.

Multi-directional limit structure: By using 3D printing technology to form micro-wedge-shaped protrusions on the surface of the silicone, the displacement of the battery cell in the X/Y/Z axes is reduced by 42%, 38% and 55% respectively.

Conclusion

The elastic silicone rubber buffering technology not only solves the problem of cell damage in a vibrating environment, but also opens up a new path for the application of high-energy-density batteries in extreme working conditions. With the integrated development of smart materials and digital monitoring technology, the mechanical reliability of lithium batteries will enter a brand-new stage, providing solid technical support for the two-wheeled electrification wave.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!