Lithium-ion battery OCV measurement technology

main content

The Open Circuit Voltage (OCV) is the potential difference between the positive and negative electrodes of a lithium battery under no-load conditions, directly reflecting the chemical equilibrium state and energy storage capacity of the battery. In the production of lithium-ion start-stop batteries for motorcycles, OCV measurement is not only a core indicator for evaluating the initial performance of the battery, but also a key link in screening consistent units and ensuring the reliability of the entire pack. This article conducts an analysis from the physicochemical mechanism, testing process, motorcycle application characteristics and technological frontiers of OCV.

1. Electrochemical equilibrium and voltage characterization

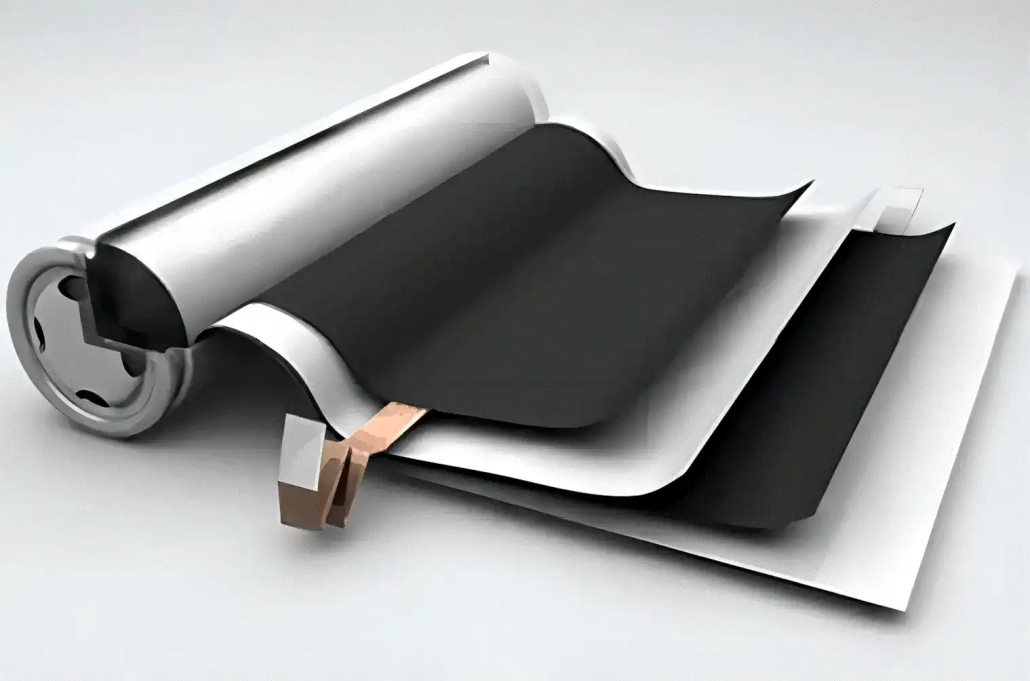

Lithium batteries achieve charging and discharging through the migration of lithium ions between the positive and negative electrodes. When the battery is at rest, the REDOX reactions between the electrode materials and the electrolyte reach a dynamic equilibrium, and the voltage measured at this time is OCV. For example, the OCV of the positive electrode of lithium iron phosphate (LiFePO₄) is approximately 3.45V when the SOC (State of Charge) is 0, while the OCV of the negative electrode graphite varies significantly with the lithium intercalation amount. When the SOC increases from 0% to 100%, the negative electrode voltage drops from 1.5V to 0.08V.

2. The correlation between OCV and SOC/SOH

OCV and SOC have a nonlinear relationship. It is necessary to establish the OCVSOC curve through experiments (such as HPPC pulse experiments). For aging batteries, the OCV curve will shift due to the loss of active substances and the decomposition of the electrolyte. For instance, after 100 cycles, the formation of Li₂CO₃ on the positive electrode surface can lead to a decrease of more than 0.5% in OCV.

3. The influence of temperature and standing time

For every 10℃ increase in temperature, OCV can produce an offset of 0.10.3mV due to the difference in reaction activation energy. Before the test, it needs to be left to stand for 12 hours to eliminate the polarization effect. For example, the OCV stability of a motorcycle battery can reach ±0.05mV after being left to stand at 25℃ for 2 hours.

1. Test equipment and precision requirements

High-precision voltmeter: Cold mirror dew point meter (such as Optidew) or impedance sensor is adopted, with a resolution of ≤1μV and an accuracy of ±0.01%.

Probe technology: The contact resistance of the OCV test probe should be ≤1mΩ to avoid the introduction of errors by the oxide layer on the copper/aluminum tabs.

Automated sorting systems: such as the Xinwei OCV/IR testing machine, which supports 400-channel parallel testing and can handle up to 4,000 PCS per hour.

2. Standardize the test procedures

Static treatment: After the battery is fully charged, it should be left to stand in an environment of 25℃±2℃ for 2 hours to eliminate polarization.

Voltage acquisition: Use the four-wire measurement method to eliminate the interference of wire resistance and record the OCV value after stabilization.

K value calculation: The self-discharge rate is calculated through two OCV measurements (such as at time points t₁ and t₂), K=OCV₁ - OCV₂. For motorcycle batteries, the requirement is K≤0.5mV/24h.

3. Environmental control

The test room should maintain a dew point of no more than 40℃ (relative humidity no more than 1%), and use dual-rotor dehumidifiers (such as Monte HG500) and micro-heat regeneration technology. The temperature fluctuation should be controlled within ±0.5℃.

Iii. Particularity of OCV Measurement for Motorcycle Start-Stop Batteries

1. Anti-vibration design adaptation

Motorcycle batteries need to withstand random vibrations at 10200Hz (with an acceleration of 1020g). During the test, vibration conditions need to be simulated to verify the stability of OCV. For instance, the tabs adopt a pre-pressed corrugated design (with a corrugation height of 0.10.2mm) to reduce the fluctuation of contact resistance.

2. Low-temperature performance verification

In an environment of 30℃, the OCV measurement needs to compensate for temperature drift. The ZrATMP type hydrocarbon solvent is adopted to keep the electrolyte active at low temperatures, and the OCV measurement error is ≤0.1mV.

3. Demand for rapid sorting

The production line requires that the OCV sorting efficiency be ≥8PPM (8 pieces per minute), integrate high-speed barcode scanners (such as Keen SR1000) and AI algorithms, and achieve data binding at the 0.1ms level.

Iv. Innovation of OCV Measurement Equipment

1. Multimodal detection technology

X-ray laser fusion: The Zeiss INSPECT system combines X-ray tomography (with a resolution of 5μm) and laser displacement sensing to simultaneously analyze the correlation between electrode alignment and OCV.

Microwave dielectric analysis: Detect the wetting state of the electrolyte through the dielectric constant distribution to predict the attenuation trend of OCV.

2. Intelligent calibration system

Integrated with the LN8541 conductivity sensor, it can monitor the purity of the rinsing water in real time (conductivity ≤1μS/cm), and automatically trigger the water change mechanism in case of abnormality to ensure the stability of the testing environment.

V. Quality Control and Industry Standards

1. Defect screening threshold

OCV consistency: The voltage difference of batteries from the same batch should be ≤±5mV.

Shell voltage (Vcase) : It is required to be ≤50mV to meet the IP67 protection grade standard.

Self-discharge rate (K value) : After 400 hours of aging test, it should meet the requirement of K≤0.3mV/24 hours.

2. Data traceability system

The MES system is adopted to achieve the full life cycle management of OCV data, and it supports the linked analysis of helium mass spectrometry leak detection (sensitivity 1×10⁻⁷Pa·m³/s) and cyclic dilation test (dilation rate ≤0.8mm after 1000 cycles).

Vi. Technical Challenges and Future Directions

1. Solid-state battery compatibility

Sulfide solid electrolytes need to adopt ALD atomic layer deposition (510nm Al₂O₃ encapsulation), and increase the upper limit of humidity for OCV testing from 10%RH to 30%RH.

2. Ai-driven prediction model

Based on digital twin technology, a dynamic correction algorithm for the OCVSOC curve is constructed to achieve an SOH (State of Health) error of ≤2%.

3. Trends in Green manufacturing

The comprehensive energy consumption of bio-based cleaning agents (such as modified polyurethane with soybean oil) combined with microwave-assisted drying is reduced by 40% compared with traditional processes.

Conclusion

OCV measurement, as the "quality gatekeeper" in lithium battery manufacturing, is evolving from single voltage detection to intelligent diagnosis that integrates multiple parameters. In the field of motorcycle start-stop batteries, through three innovations - high-precision probe technology (such as 5μm linear array CCD), anti-vibration design optimization (pre-pressed corrugated TAB), and AI sorting systems (such as Datafeng X-ray equipment) - the OCV measurement accuracy has exceeded ±0.1mV, providing a core guarantee for battery consistency in high-vibration and wide-temperature range scenarios. In the future, with the popularization of solid electrolyte and dry electrode technologies, OCV measurement may be deeply integrated with processes such as electrode sheet forming and interface modification, opening up a new dimension of quality control in battery manufacturing.

RELATED BLOG

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

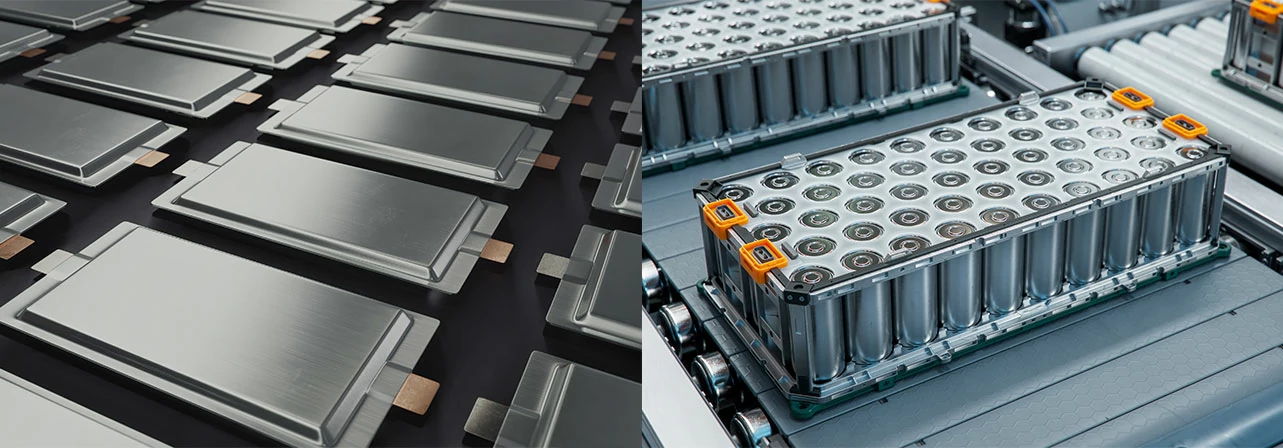

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!