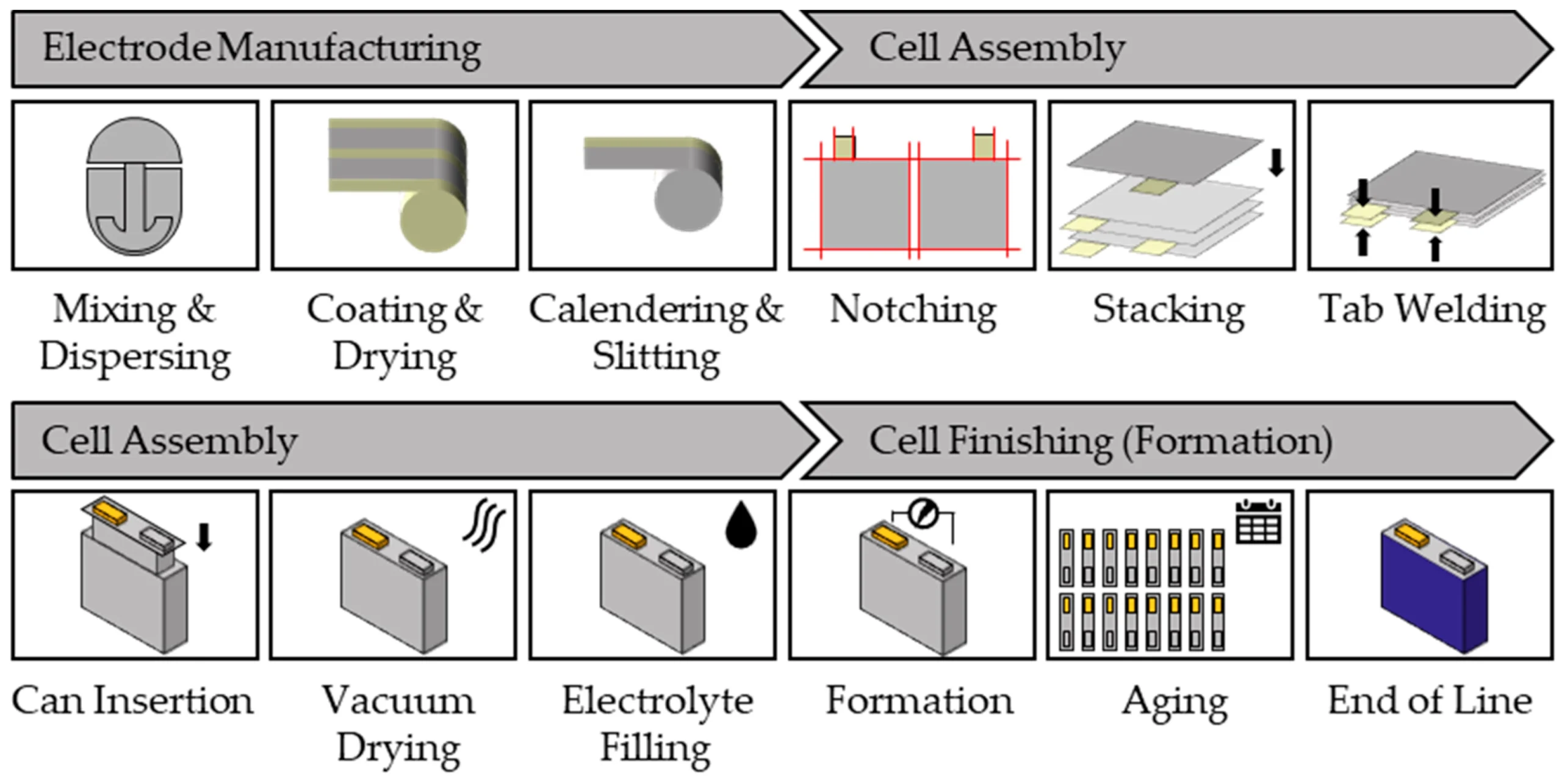

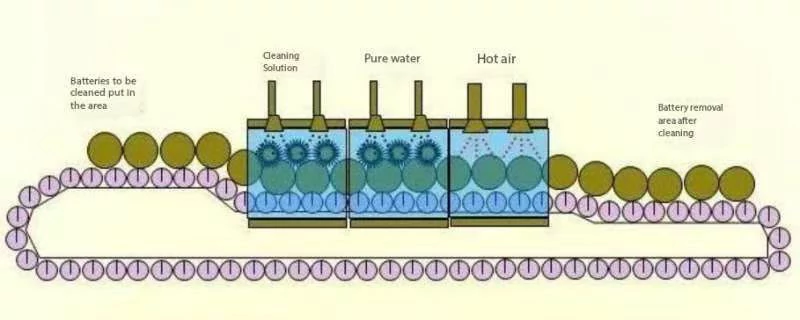

Lithium-ion battery drying and storage process

main content

Dry storage is a key post-treatment process in the manufacturing of lithium-ion batteries. By placing the cleaned batteries in an ultra-low humidity environment, the risk of moisture erosion to the electrodes, separators and electrolyte is eliminated. For lithium-ion start-stop batteries on motorcycles, dry storage is directly related to the battery's cycle life, low-temperature performance and shock resistance reliability. It is necessary to achieve microgram-level moisture control through precise humidity regulation, material compatibility and intelligent monitoring.

1. Water erosion pathways and hazards

Electrode oxidation: Moisture reacts with the positive electrode active material (such as NCM811) to form LiOH/Li₂CO₃, resulting in lithium loss (0.5% capacity loss per 500ppm H₂O) and an increase of 1530% in the cycle expansion rate.

Electrolyte decomposition: H₂O reacts with LiPF₃ to form HF (the SEI film dissolves when the concentration is ≥100ppm), accelerating the stripping of graphite at the negative electrode and increasing the internal resistance by 2050mΩ.

Diaphragm pore blockage: Moisture adsorption causes the closed-cell temperature of the diaphragm (such as PE/PP composite membrane) to drop by 510℃. Under high-temperature working conditions, it is prone to cause micro-short circuits.

2. Drying kinetics model

The diffusion of moisture follows Fick's second law: \(\frac{\partial C}{\partial t} = D \frac{\partial^2 C}{\partial x^2} \), where the diffusion coefficient D is exponentially related to the temperature T (D= D₀exp(Ea/RT)). Due to the compact shell of the motorcycle battery (wall thickness 0.61.2mm), it needs to be maintained at 4560℃ for 1224 hours to ensure that the internal water activity (Aw) is ≤0.65.

Ii. Particularity of Dry Storage for motorcycle start-stop Batteries

1. Seismic design adaptability

Structural strengthening: The 6063T6 aluminum alloy shell (yield strength ≥220MPa) is adopted, and the moisture absorption rate of the surface oxide layer is 60% lower than that of 304 stainless steel. The drying time can be shortened to 812 hours.

Gradient drying: Staged heating (25℃→45℃→60℃) combined with vacuum gradient (50kPa→90kPa) to prevent stress cracks in the electrode sheet core due to rapid dehydration (crack rate ≤0.1%).

2. Challenges in low temperature and high humidity environments

Moisture absorption inhibitor: Trimethyl phosphate (TMP, accounting for 23 wt-%) is added to the electrolyte to form a hydrophobic SEI film, making the equilibrium moisture content of the battery cell ≤15ppm (the conventional formula is 3050ppm).

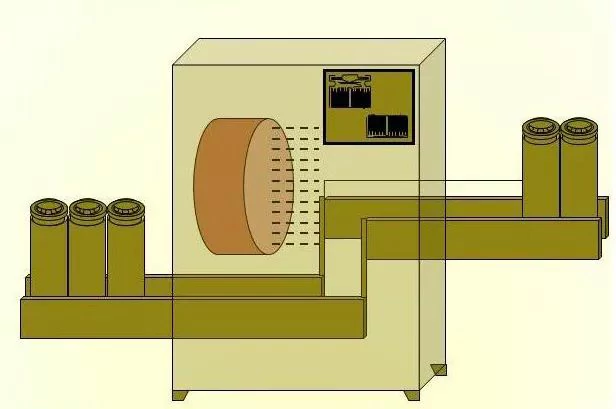

Dew point control: The dew point temperature in the drying room is ≤40℃ (corresponding to a relative humidity of ≤1%RH). A combination of a dual-rotor dehumidifier (such as Monte HG500) and micro-heat regeneration is adopted, reducing energy consumption by 30% compared to traditional solutions.

Iii. Key Process Parameters and Equipment Innovation

1. Precise control of temperature and humidity

Temperature curve: Heating rate ≤2℃/min, fluctuation ±0.5℃ during the constant temperature stage, avoiding deformation of the TAB caused by thermal stress (wave edge ≤0.3mm).

Humidity monitoring: Cold mirror dew point meters (such as Optidew) are linked with impedance sensors, achieving an accuracy of ±0.1℃dp, and real-time feedback is provided to adjust the dehumidification unit.

2. Intelligent drying system

Vacuum pulse technology: Alternating vacuuming (95kPa) and nitrogen backfilling (purity ≥99.999%), the moisture diffusion efficiency is increased by 50%, and the drying time is shortened to two-thirds of the conventional process.

Machine vision monitoring: Integrated with a 5μm linear array CCD to detect condensate water on the shell surface, the AI algorithm triggers the secondary drying process when the water stain area is ≥0.01mm².

1. Moisture content detection

Karl Fischer method: The moisture content of the electrolyte is determined by coulometric method (standard ≤20ppm), and the moisture content of the gas phase inside the shell is analyzed by headspace gas chromatography (GC2030) (≤50ppm).

Weight loss method verification: After baking at 105℃ for 2 hours and weighing, the residual moisture content of the motorcycle battery should be ≤100mg/Ah.

2. Environmental simulation test

High and low temperature cycling: After alternating at 40℃ to 85℃ for 100 times, disassemble and test the moisture content of the diaphragm (requirement ≤0.02wt.%).

Vibration-humidity coupling: According to the SAE J2380 standard, when a random vibration of 10200Hz is applied at a humidity of 90%RH for 21 hours, the humidity change inside the shell is ≤3%RH.

V. Technical Challenges and Frontier Directions

1. Solid-state battery compatibility upgrade

Sulfide electrolyte protection: Al₂O₃ atomic layer deposition (ALD) encapsulation (510nm thickness) is adopted to increase the upper limit of humidity tolerance for dry storage from 10%RH to 30%RH.

Dry electrode process: The solvent-free coating technology ensures that the initial moisture content of the electrode is ≤50ppm, and the drying time can be compressed to 46 hours.

2. Green drying technology

Bio-based desiccants: Modified starch adsorbents (such as corn starch grafted with acrylic acid) have a moisture absorption capacity of up to 300mg/g, the regeneration temperature drops from 120℃ to 80℃, and the comprehensive energy consumption is reduced by 40%.

Waste heat recovery system: The exhaust heat from the drying room is recovered by a heat pump (COP≥3.5) to preheat the intake air, achieving a closed loop of energy consumption.

Conclusion

Dry storage, as the "micro-water defense line" for lithium-ion start-stop batteries in motorcycles, is evolving from extensive moisture control to molecular-level moisture management. Through the collaborative innovation of vacuum pulses, ALD packaging and intelligent monitoring systems, modern drying processes have achieved a leap in moisture control accuracy from the ppm level to the ppb level. In the future, with the popularization of dry manufacturing and solid-state batteries, dry storage will be deeply integrated with material modification and interface regulation, providing a more weather-resistant and stable "energy core" for new energy motorcycles.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!