Heat dissipation design of protective shell

main content

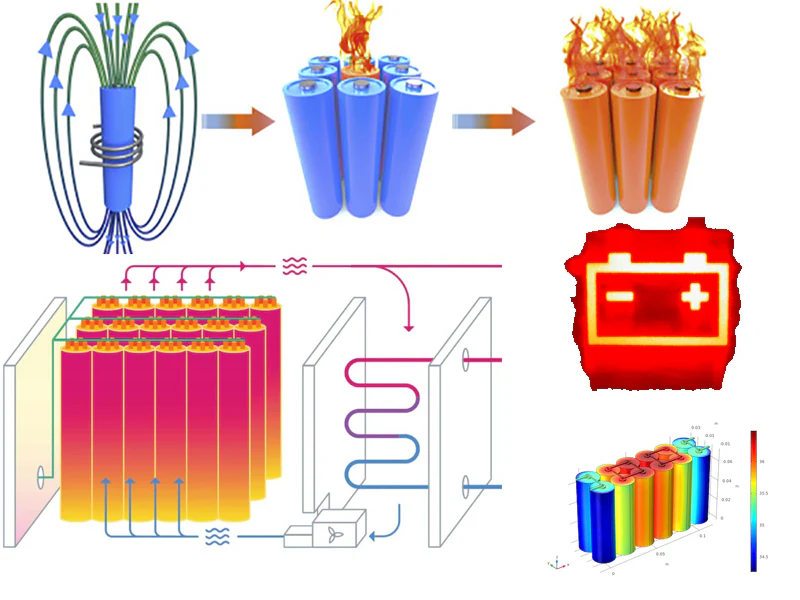

When the motorcycle starts the lithium battery at an instantaneous high rate discharge (more than 10C), the temperature of the battery core can soar more than 15 ° C in 30 seconds. If the heat dissipation is poor, it will lead to an increase of 20% in internal resistance, accelerate the capacity attenuation by 3 times, and even cause the risk of thermal runaway. The research shows that the optimized heat dissipation design can make the battery working temperature stable in the range of 25-45℃, the temperature difference is controlled within ±2℃, and the cycle life is increased by 50%.

Optimization of material thermal conductivity

1. High thermal conductivity composite material

Metal matrix composite: The 6061 aluminum alloy shell (thermal conductivity of 160W/(m·K)) combined with graphene coating (thermal conductivity of 1500W/(m·K)) improves the overall thermal conductivity of the shell to 200 times that of the traditional plastic solution.

Polymer based innovation: carbon fiber reinforced polyamide (PA66+40%CF) achieves a thermal conductivity of 15W/(m·K) at a density of 1.6g/cm³, which is 75 times higher than ordinary plastics, while maintaining impact strength of 120kJ/m².

2. Phase change energy storage material integration

The paraffin/expanded graphite composite phase change material (latent heat ≥180J/g) was filled in the gap of the cell core, and the Joule heat generated by the instantaneous high-current discharge was absorbed through the solid-liquid phase change, so that the temperature rise rate at 10C discharge was reduced from 5℃/min to 1.2℃/min.

structural design innovation

1. Bionic heat dissipation topology

Honeycomb flow channel design: hexagonal honeycomb structure (aperture 5-20mm) is constructed inside the shell, which increases the heat dissipation efficiency by 40% and reduces the air resistance by 35% by increasing the convective contact area.

Snake-like micro-channel liquid cooling: integrated 0.8mm width micro-channel in the aluminum alloy shell, with ethylene glycol aqueous solution circulation (flow rate of 0.5m/s), the temperature gradient of the cell surface can be compressed from 8℃ to 2℃.

2. Gradient cooling fin system

The copper and aluminum composite fins with a thickness of 0.5mm (spacing of 3mm) are used to optimize the inclination Angle (15°-25°) by Computational Fluid dynamics (CFD), and the cooling power density is 15W/cm² under the natural convection current, which is 3 times higher than that of the traditional plate structure.

active and passive heat dissipation coordination

1. Intelligent liquid cooling system

Dynamic temperature control strategy: BMS is based on Extended Kalman Filter (EKF) algorithm to monitor the temperature of the battery core in real time. When the temperature is > 45℃, the liquid cooling pump (power 50W) is started, and the coolant flow rate is increased from 0.2L/min to 1.5L/min, and the temperature drop rate is 0.8℃/s.

2. Air cooling reinforced design

The Z-shaped labyrinth airway (opening rate of 30%) is set on both sides of the shell, and the air flow is accelerated to 12m/s through the Venturi effect. With the PTC auxiliary heating module, the effective heat dissipation at -20℃ is realized.

Conclusion

From the biomimetics topology of honeycomb flow channels to the microscopic thermal regulation of phase change materials, the heat dissipation design of motorcycle lithium battery protective casing is breaking through the traditional thermodynamic boundaries. At present, micro-channel liquid cooling and gradient fin technology have achieved ±2℃ average temperature control at 10C discharge, and the fusion of immersion cooling and smart materials will provide a more efficient heat dissipation solution for high energy density batteries.

RELATED BLOG

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!