Exploration of the Production Process of Lithium-ion Start-Stop Batteries for Motorcycles

main content

In today's motorcycle field, lithium-ion start-stop batteries are gradually becoming the mainstream choice. It is not only small in size and light in weight, but also has the advantages of high energy density and long service life, which greatly enhances the starting performance and endurance of motorcycles. Behind these advantages lies the support of complex production processes. This article will conduct an in-depth analysis of the production process of lithium-ion start-stop batteries for motorcycles based on the general production procedures of lithium batteries.

Preface

The production process of lithium-ion start-stop batteries for motorcycles is a perfect integration of technology and craftsmanship. From the selection of raw materials to the inspection of the final products, every step embodies the efforts and wisdom of the engineers. This article will take you into this mysterious production world to explore it.

The first step of production is the homogenization of the negative electrode. The negative electrode material is one of the key factors for battery performance. In lithium-ion start-stop batteries for motorcycles, materials such as graphite are usually selected as the negative electrode. These materials are ground into fine particles and then mixed with binders, conductive agents, etc., to form a uniform slurry. This process requires precise control of the concentration, viscosity and particle size of the slurry to ensure that the negative electrode material can be evenly distributed in the subsequent processes, providing stable performance for the battery.

Next comes the homogenization of the positive electrode. The cathode material is usually a lithium-containing metal oxide, such as lithium iron phosphate, lithium cobalt oxide, etc. These materials also need to be ground and mixed to form the cathode slurry. The quality of the positive electrode slurry directly affects the energy density and discharge performance of the battery. Therefore, this stage has extremely high requirements for the precision of the production equipment and the experience of the operators.

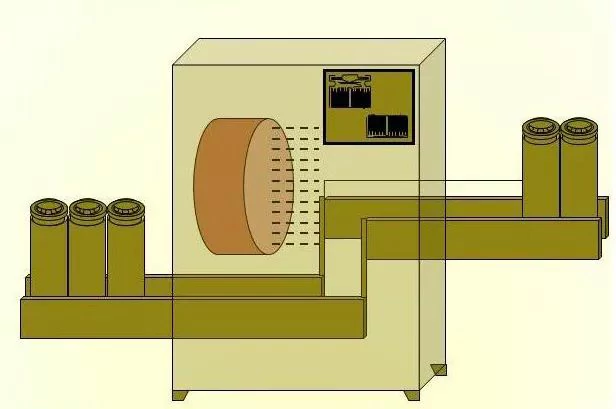

Coating involves evenly applying the negative and positive electrode pastes respectively onto aluminum foil and copper foil. Aluminum foil and copper foil, as current collectors, play the role of collecting and conducting electric current. The thickness and uniformity of the coating are crucial to the performance of the battery. If the coating is not uniform, it may cause uneven current distribution inside the battery, thereby affecting the battery's lifespan and safety. In the production of lithium-ion start-stop batteries for motorcycles, advanced coating equipment is usually adopted. Through precise control and monitoring systems, the quality of the coating is ensured.

Coating involves evenly applying the negative and positive electrode pastes respectively onto aluminum foil and copper foil. Aluminum foil and copper foil, as current collectors, play the role of collecting and conducting electric current. The thickness and uniformity of the coating are crucial to the performance of the battery. If the coating is not uniform, it may cause uneven current distribution inside the battery, thereby affecting the battery's lifespan and safety. In the production of lithium-ion start-stop batteries for motorcycles, advanced coating equipment is usually adopted. Through precise control and monitoring systems, the quality of the coating is ensured.

Slitting is the process of cutting the compacted electrode sheets to the required dimensions. This process needs to ensure the cutting accuracy to guarantee the dimensional consistency of the battery. In the production of lithium-ion start-stop batteries for motorcycles, due to their relatively small volume, higher precision is required for slitting. Precise slitting can ensure that the battery fits perfectly when installed on the motorcycle, and it also helps to improve the assembly efficiency of the battery.

The purpose of baking is to remove the moisture and organic solvents in the electrode sheet. The presence of moisture and organic solvents can affect the performance and safety of batteries. During the baking process, it is necessary to strictly control the temperature and time to ensure the drying degree of the electrode sheet. For lithium-ion start-stop batteries on motorcycles, rapid and uniform baking can enhance production efficiency while ensuring battery quality.

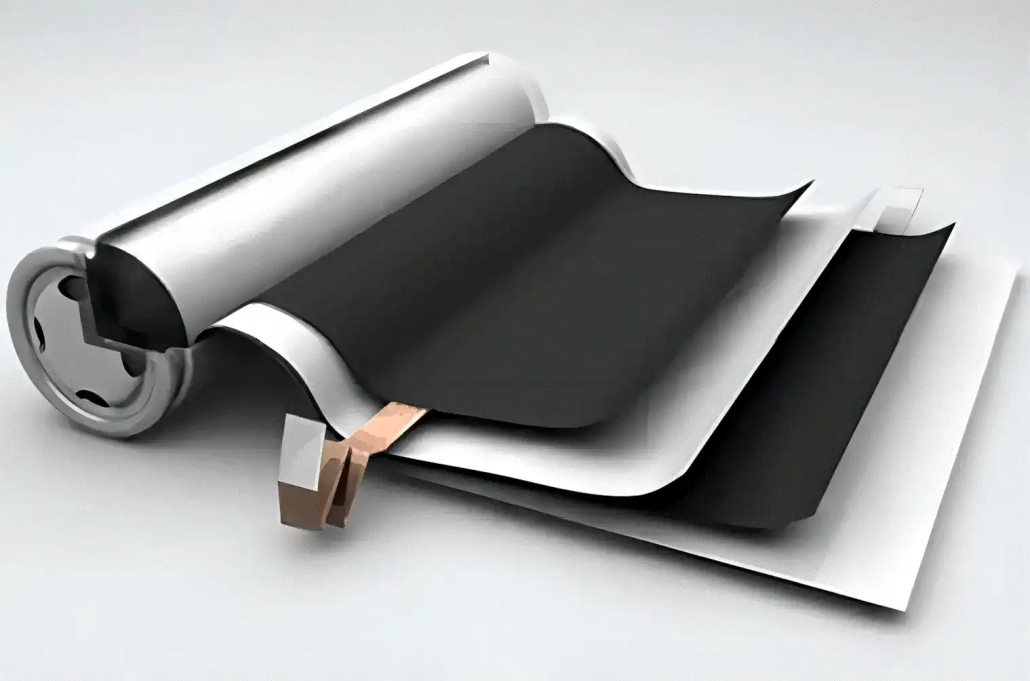

Winding is the process of winding the positive electrode sheet, separator and negative electrode sheet together in a certain order to form the battery cell. The diaphragm plays a role in isolating the positive and negative electrodes and preventing short circuits. The tightness and consistency of winding have a direct impact on the performance of the battery. In the production of lithium-ion start-stop batteries for motorcycles, as they need to withstand certain vibrations and shocks, the quality of winding is particularly important. Tight and uniform winding can enhance the structural stability of the battery and extend its service life.

Inserting the wound battery cells into the battery casing is the process of placing them inside the battery case. The casing not only serves to protect the internal structure of the battery but also provides certain mechanical support. In the production of lithium-ion start-stop batteries for motorcycles, the design of the casing needs to take into account the installation method of the battery and the usage environment of the motorcycle. A suitable casing can enhance the battery's shock resistance and water resistance, thereby increasing its reliability on motorcycles.

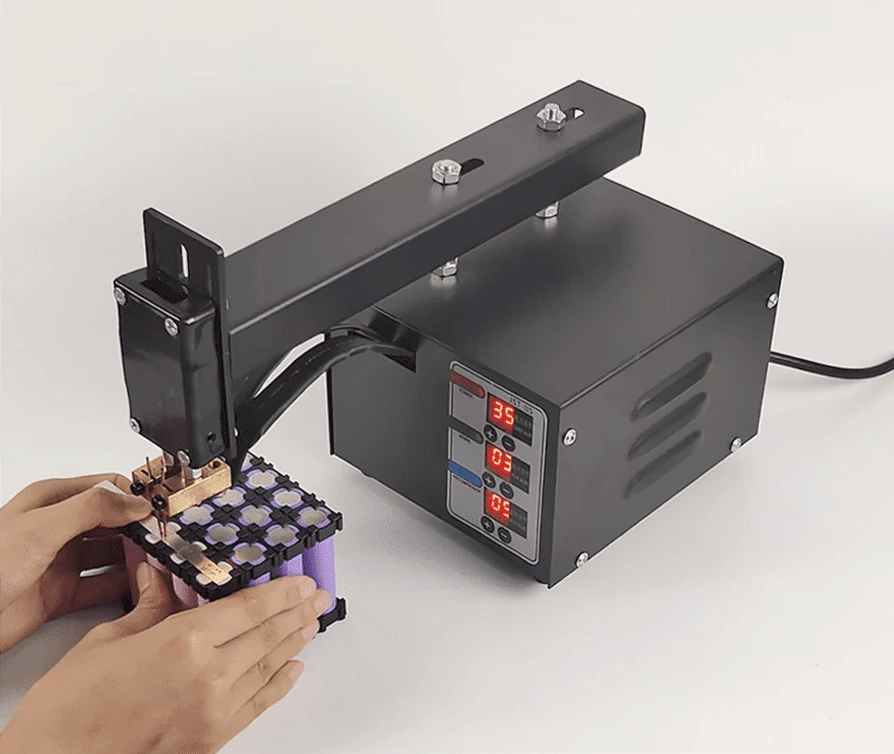

Spot welding is used to connect the battery cells to the casing to ensure the reliable electrical connection of the battery. The quality of welding directly affects the electrical conductivity and safety of batteries. In the production of lithium-ion start-stop batteries for motorcycles, high-precision welding equipment and strict quality control measures need to be adopted to ensure the strength and conductivity of the welding points.

Liquid injection is to inject electrolyte into the interior of the battery. The electrolyte plays a role in conducting ions in the battery and is the key for the battery to operate normally. During the liquid injection process, it is necessary to strictly control the injection volume and purity of the electrolyte to ensure the performance and safety of the battery. For lithium-ion start-stop batteries on motorcycles, an appropriate electrolyte can enhance the battery's low-temperature performance and rapid charging and discharging capabilities, meeting the usage requirements of motorcycles in various environments.

The welded cap is to weld the battery cap and the casing together to form a sealed battery structure. The quality of welding directly affects the sealing performance and safety of batteries. In the production of lithium-ion start-stop batteries for motorcycles, advanced welding techniques and strict quality inspection methods need to be adopted to ensure the firmness and sealing of the welding.

Cleaning is to remove impurities and residues from the surface of the battery. This step can enhance the appearance quality and reliability of the battery. In the production of lithium-ion start-stop batteries for motorcycles, a clean battery surface helps improve their installation accuracy and aesthetic appeal on motorcycles.

Dry storage involves storing the cleaned batteries in a dry environment. This step can prevent the battery from getting damp, which may affect its performance and lifespan. For lithium-ion start-stop batteries on motorcycles, dry storage is an important link to ensure their factory quality.

Checking alignment is to inspect the alignment of each component inside the battery. If the components are not aligned properly, it may cause a short circuit or poor contact inside the battery. In the production of lithium-ion start-stop batteries for motorcycles, precise alignment detection can effectively enhance the safety and reliability of the batteries.

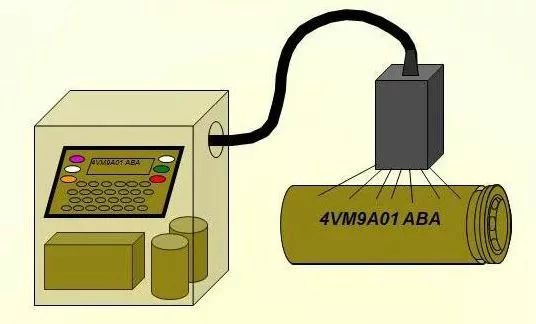

Shell inkjet printing is the process of printing product information such as model and production date on the battery shell. This step not only helps with the identification and traceability of the product, but also enhances its aesthetic appeal. In the production of lithium-ion start-stop batteries for motorcycles, clear inkjet codes can facilitate users' identification and selection of products.

Formation is a key process in battery production. By applying a certain current to the battery, the active substances on the positive and negative electrodes of the battery are excited, thereby endowing the battery with the ability to discharge. This process can activate the chemical reactions inside the battery, enabling the battery to reach its optimal performance state. For lithium-ion start-stop batteries on motorcycles, the quality of formation directly affects their starting performance and service life.

OCV (open-circuit voltage) measurement is used to detect the voltage of a battery when it is not connected to a load. This step can evaluate the initial performance and consistency of the battery. In the production of lithium-ion start-stop batteries for motorcycles, accurate OCV measurement helps to screen out batteries with excellent performance and improve the overall quality of the products.

Normal-temperature storage involves keeping the battery at room temperature for a period of time. This step can further stabilize the battery's performance, making it more reliable in subsequent use. For lithium-ion start-stop batteries of motorcycles, normal temperature storage is a key link to ensure their stable operation in different seasons.

Capacity separation is the process of classifying batteries according to their capacity. Due to the possible capacity differences of batteries during the manufacturing process, batteries can be classified into different grades through capacity separation to meet the needs of different users. In the production of lithium-ion start-stop batteries for motorcycles, precise capacity separation can enhance the market competitiveness of the products and provide users with more accurate product choices.

The final process is to conduct a comprehensive inspection and packaging of the battery. The inspection includes visual inspection, performance testing, etc., to ensure that the battery meets the quality standards. The packaging needs to ensure the safety and integrity of the battery during transportation and storage. For lithium-ion start-stop batteries on motorcycles, good packaging can prevent the batteries from being damaged during transportation and ensure they can safely reach the users.

Conclusion

The production process of lithium-ion start-stop batteries for motorcycles is complex and meticulous. Every link plays a crucial role in the performance and quality of the battery. Through strict quality control and advanced production technology, high-performance and highly reliable lithium-ion start-stop batteries for motorcycles can be produced, providing strong power support for the start-up and operation of motorcycles. With the continuous advancement of technology, it is believed that the lithium-ion start-stop batteries for motorcycles in the future will be more efficient, environmentally friendly and safe.

RELATED BLOG

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!