BMS's low-temperature preheating technology

main content

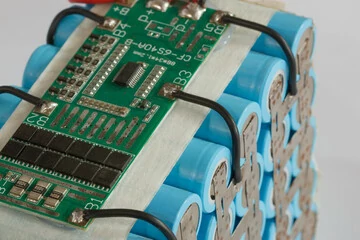

In an extremely cold environment of -30℃, the capacity of traditional lead-acid batteries can decline by up to 60%, while lithium batteries often face the predicament of cold start failure due to the sharp increase in the viscosity of the electrolyte (rising to 15 times that at room temperature at -20℃) and the sudden drop in the lithium-ion diffusion coefficient (on the order of 10⁻¹⁴ cm²/s). Studies show that for every 1℃ increase in battery temperature, the internal resistance can decrease by 3% to 5%, and the discharge capacity can recover by 2% to 3%. The motorcycle starting lithium battery management system (BMS) is breaking through the physical limit of low temperatures by integrating preheating technology.

The Scientific Nature of the Low-temperature Startup Issue

Electrochemical performance degradation

Electrolyte solidification effect: The ionic conductivity of conventional carbonate electrolytes drops to 20% of that at room temperature at -30℃, and the lithium ion migration energy barrier rises from 0.3eV to 0.5eV.

Interfacial dynamic hysteresis: The lithium-ion intercalation rate of the graphite anode drops fivefold at low temperatures, resulting in a 0.2V increase in concentration polarization voltage and causing a capacity drop.

Deterioration of physical properties

Nonlinear increase in internal resistance: At -20℃, the ohmic internal resistance (R₀) of lithium iron phosphate batteries reaches three times that at room temperature, the polarization internal resistance (R_p) increases by eight times, and the instantaneous starting current (CCA) decreases by 50%.

The impedance of the SEI film doubles: The lithium-ion diffusion impedance (R_SEI) of the solid electrolyte interface film (SEI) surges from 50Ω·cm² at room temperature to 200Ω·cm², intensifying the energy transfer loss.

Technological Breakthroughs in Preheating methods

External heating technology

PTC ceramic heating film: It achieves self-limiting temperature control through positive temperature coefficient materials (power density 2-5W/cm²), integrated into the cell gap, and can heat the battery pack from -30℃ to 0℃ within 10 minutes.

Liquid thermal circulation system: It adopts ethylene glycol - water solution circulation pipeline, combined with microchannel heat sink, to achieve ±2℃ uniform temperature control, and the heat conversion efficiency reaches 85%.

Internal self-heating technology

Ac impedance heating: By applying an AC current of 1-10 KHZ (current density ≤2C), heat is generated through the Joule effect of the battery's internal resistance. Within 700 seconds, a temperature rise of 47.6℃ can be achieved, with a SOC loss of less than 1%.

Dc pulse heating: Alternately apply charge and discharge pulses (duty cycle ≤30%), maintain SOC stability through reverse cancellation of polarization voltage, and achieve a heating rate of 1.2℃/min.

Optimization Paths for Intelligent Heating Strategies

Temperature-triggered threshold control

Hierarchical start-up mechanism: PTC heating is initiated when the cell temperature is less than -20℃. Switch to AC self-heating within the range of -20℃ to 0℃ to prevent local overheating and decomposition of the electrolyte.

Dynamic power regulation: Based on the extended Kalman Filter (EKF), it estimates the temperature gradient of the battery cells in real time and automatically adjusts the heating power (50-200W) within a temperature difference of 10℃.

Multi-parameter collaborative control

Soc-soh compensation algorithm: Compress the state of charge (SOC) estimation error from ±5% to ±2% at low temperatures, and dynamically correct the upper limit of heating power in combination with the State of health (SOH).

Polarization voltage limiting strategy: Control the polarization voltage to ≤50mV through the three-dimensional lookup table (SOC-T-OCV) to prevent the growth of lithium dendrites.

Energy efficiency optimization

Phase change energy storage coupling: Filling the gap of the battery cell with paraffin/expanded graphite composite material (latent heat ≥180J/g) reduces the preheating energy consumption by 40%.

Waste heat recovery technology: Utilizing the waste heat from the motor controller (with an efficiency of ≥30%), it is conducted to the battery pack through heat pipes, reducing reliance on external energy.

Conclusion

From the Joule heat effect of PTC films to the microscopic heat generation mechanism of AC impedance, the BMS low-temperature preheating technology for motorcycle lithium batteries is breaking through the boundary between the physical properties of materials and the energy efficiency of the system.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!