Activate the terminal protection of the lithium battery

main content

Motorcycle start-up lithium battery is the core component of the power system, and its terminal design is directly related to the energy transmission efficiency and system security. Research shows that terminal contact failure accounts for more than 34% of lithium battery system failures, and vibration shock, high current overload and environmental corrosion under extreme working conditions further aggravate the risk of terminal damage. This paper analyzes the protection technology principle and innovative practice of motorcycle lithium battery terminal from three dimensions of material protection, structural seal and electrical protection.

Material protection: balance design of electrical conductivity and corrosion resistance

1. Application of highly conductive composite materials

Motorcycle lithium battery terminals need to meet the requirements of high conductivity and mechanical strength. At present, the mainstream solution uses copper tellurium (C14500) or chromium zirconium copper (C18150) substrate, whose conductivity can reach 85%-90%IACS, tensile strength can reach more than 380MPa, and corrosion resistance is improved by surface coating technology. For example, nickel-titanium memory alloy coating can still maintain a stable contact pressure in the temperature range of -40℃ to 150℃, and no red rust is generated in the salt spray test for 2000 hours.

2. Gradient composite structure innovation

In order to cope with high current impact, some high-end batteries use composite terminals with porous copper core and carbon fiber reinforcement. The porosity of the structure is 30%, the weight is reduced by 50%, and the thermal conductivity is increased to 400W/(m·K), which effectively reduces the risk of Joule heat accumulation. Experimental data show that the temperature rise rate of the design is 60% lower than that of the traditional terminal at 10C discharge.

seal design: leakage prevention and seismic double protection

1. Pole column sealing technology breakthrough

The combination of PTFE sealed insulators and silicon nitride ceramic gasket is adopted to achieve IP67 protection level through the triple seal structure:

The first sealing layer: brazing of stainless steel sleeve and end cap, leakage rate < 1.0×10⁻⁷ Pa·m³/s;

The second sealing layer: butterfly nickel-based alloy gasket through 20kN preload compression ceramic gasket, compensation thermal expansion and cold contraction deformation;

The third sealing layer: the surface of the pole column is processed with R0.5 annular nicks to enhance the fit with the sealing material.

2. Dynamic buffer structure optimization

The elastic silica gel buffer layer (shore hardness 10HA) is set at the terminal root, and the honeycomb support design can disperse the stress peak of 15G vibration impact from 3MPa to 0.7MPa. The measured data of Lishen battery show that the structure makes the terminal plug and unplug life from 500 times to 1500 times, and the contact resistance fluctuation range is compressed to ±5%.

Electrical protection: active defense of overload and short circuit

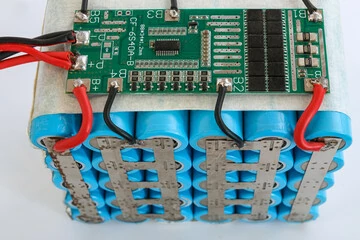

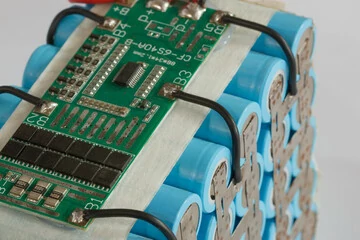

1. Hardware protection circuit integration

TLBJ04D protection board is used to integrate the following core functions:

Overcurrent protection: real-time monitoring of current density, when the instantaneous current exceeds 150A, MOSFET can cut off the loop within 10ms;

Short circuit protection: through the combination of bidirectional TVS tube and self-recovery fuse, withstand 100V surge voltage impact;

Equalization management: hardware equalization current up to 10A, eliminate 100mV cell pressure difference within 5 minutes.

2. Intelligent relay control

A magnetic hold relay module is introduced to activate the contacts by a pulse current at the instant the key switch is turned on. The design can withstand 800A cold start current, contact resistance ≤0.15mΩ, compared with the traditional mechanical relay life 3 times longer.

Conclusion

From the molecular seal of silicon nitride ceramics to the intelligent perception of piezoelectric films, the terminal protection technology of motorcycle lithium batteries is breaking through the physical limits of materials and the boundaries of system energy efficiency. At present, the gradient composite structure and magnetic retention relay technology have achieved stable transmission at 800A cold start current, and the fusion of digital twin and solid state interface will further expand the reliability boundary of the terminal.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!