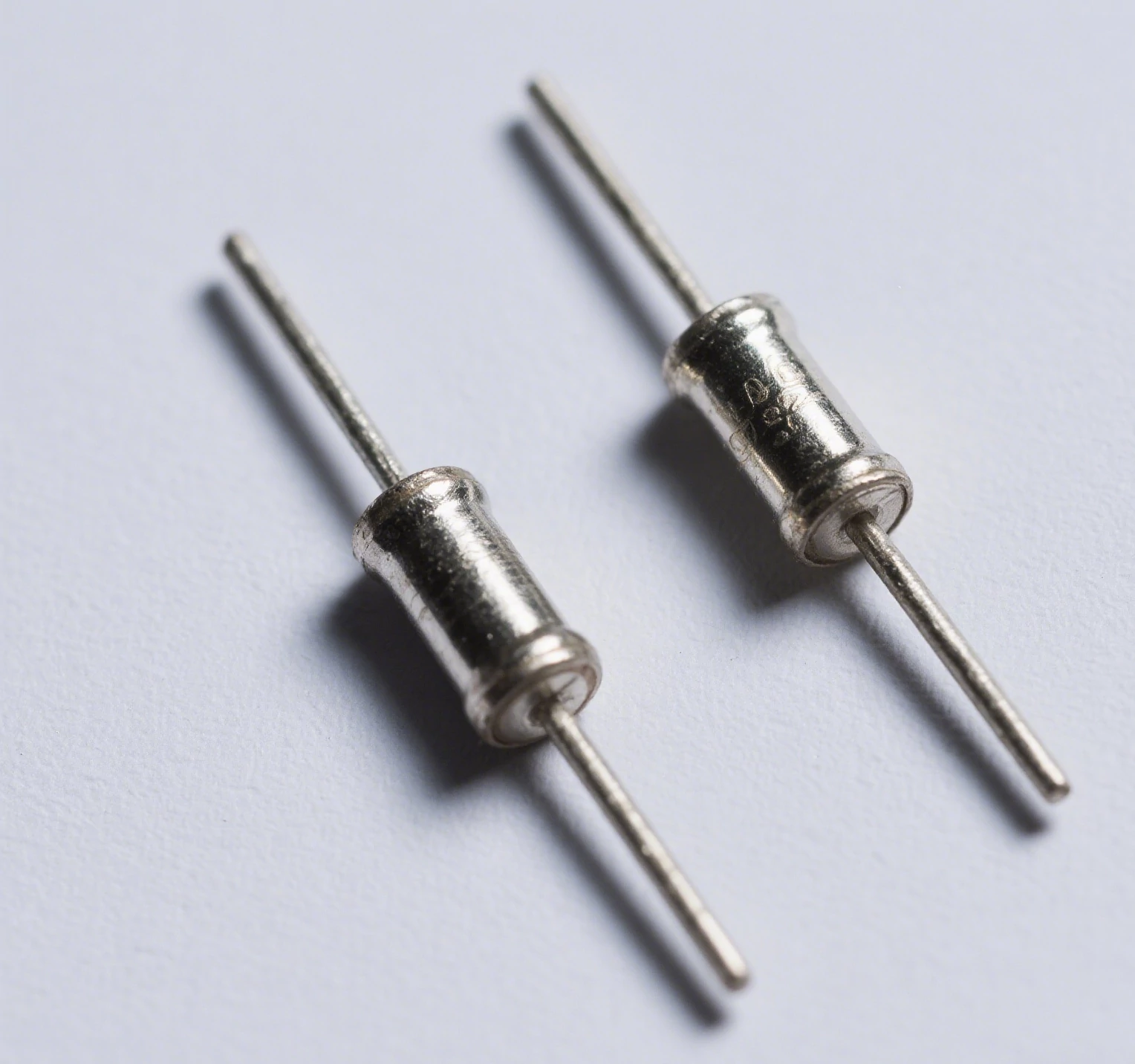

Battery cell pressure relief valve

main content

In the current era of rapid technological development, as the core power source of various electronic devices and new energy vehicles, the safety of batteries is of vital importance. The battery cell pressure relief valve, as a key component to ensure the safe operation of the battery, plays an indispensable role. This article will delve deeply into the working principle, significance and unique position of the battery cell pressure relief valve in battery safety protection.

Working Principle of Pressure Relief Valve

During the use of battery cells, the internal pressure may increase for various reasons. For instance, under abnormal conditions such as overcharging, short circuit or high temperature of the battery, the chemical reactions inside the battery intensify, generating a large amount of gas. When the internal pressure exceeds the set safety threshold (usually 20kPa), the pressure relief valve will automatically open. This pressure value is obtained through precise calculation and strict testing. It can not only effectively prevent the explosion risk caused by excessive internal pressure of the battery, but also maintain the battery's sealing performance under normal working conditions. The opening method of a pressure relief valve is usually through a special mechanical structure or material. When the set pressure is reached, it undergoes deformation or rupture, thereby providing a release channel for gas and expelling the excess gas to the outside of the battery, rapidly reducing the internal pressure of the battery to a safe range.

The Importance of Pressure Relief Valves

Preventing explosion: Excessive internal pressure of the battery is one of the main causes of battery explosion. The existence of the pressure relief valve is like a solid defense line. When the pressure exceeds the safe range, it can release gas in time to prevent the battery casing from cracking or even exploding due to excessive pressure, thereby effectively protecting the personal safety of the user and the safety of the surrounding equipment.

Extending battery life: During the normal operation of the battery, there may occasionally be a slight increase in internal pressure. The pressure relief valve can promptly discharge excess gas, preventing the internal pressure of the battery from remaining at a high level for a long time, reducing adverse effects on the internal structure and chemical substances of the battery, thereby helping to extend the service life of the battery and maintain its stable performance.

Ensuring the normal operation of equipment: For electronic devices and new energy vehicles that rely on battery power, the safety and stability of the battery directly affect the normal operation of the equipment. The reliable operation of the pressure relief valve can ensure that the battery can safely and stably output electrical energy under various working conditions, avoiding equipment damage or unusability caused by battery failure, and improving the reliability of the equipment and user experience.

Application Status and Development Trends of Pressure Relief Valves

The application of pressure relief valves in battery cells has become quite widespread, especially in cylindrical cells where they are more common. With the continuous development of battery technology, the requirements for pressure relief valves are getting higher and higher. On the one hand, researchers are striving to enhance the sensitivity and reliability of the pressure relief valve, enabling it to open and close within a more precise pressure range. On the other hand, new materials and structures are also being explored to meet the demands of batteries with higher energy density and more complex working conditions. For instance, some new types of pressure relief valves adopt smart materials and can adaptively adjust according to various factors such as temperature and pressure inside the battery, further enhancing the safety and performance of the battery.

Conclusion

Although the battery cell pressure relief valve is small, it bears the significant responsibility of ensuring the safe operation of the battery. It can effectively prevent battery explosion at critical moments, protect the safety of users, and also help extend battery life and ensure the normal operation of the equipment. With the continuous advancement of battery technology, we have every reason to believe that the technology of pressure relief valves will also keep innovating and improving, providing more reliable guarantees for battery safety and promoting the development of the battery industry to a new height.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!