Negative material - "storage warehouse" for lithium batteries

main content

If the positive electrode material is the "energy heart" of lithium batteries, then the negative electrode material is the "energy storage warehouse" that silently carries lithium ions. During the charging and discharging process, the shuttling of lithium ions between the positive and negative electrodes is essentially the ultimate test of the negative electrode material's ability to intercalate and release lithium. This article will conduct an in-depth analysis of the technical characteristics of mainstream anode materials.

Graphite: The guardian of classic layered structures

Chemical structure: Hexagonal crystal system layered structure, with a layer spacing of 0.335nm, forming a "highway" for lithium ion intercalation.

Core advantages:

Outstanding stability: The volume expansion rate is only 10%, and the cycle life exceeds 1,000 times.

Excellent electrical conductivity: The interlayer electron migration rate reaches 10⁴ S/m, supporting fast charging above 3C.

Cost advantage: The mass production cost is as low as 3 US dollars per kilogram, occupying 80% of the market share.

Performance limit:

The theoretical capacity of 372mAh/g is approaching the physical limit.

Poor low-temperature performance (capacity attenuation to 60% at -20℃).

Typical applications: consumer electronics batteries, standard-range versions of electric motorcycles.

Silicon-based materials: Revolutionaries in energy storage density

Chemical mechanism: Silicon forms Li₃ with lithium. Youdaoplaceholder0 ₅Si alloy, providing a theoretical capacity of 4200mAh/g (11 times that of graphite).

Core breakthrough:

Nanostructure design: Prepare 100nm silicon particles and reduce the volume expansion rate from 300% to 150%;

Carbon-based composite technology: Graphene encapsulates silicon particles to form an "egg yolk - eggshell" structure, increasing the cycle life from 50 times to 500 times.

Pre-lithiation process: Compensating for the lithium loss in the first cycle, the Coulombic efficiency is increased from 75% to 92%.

Technical challenges:

Expansion stress causes electrode powdering, and elastic binders (such as polyimide) need to be developed;

The consumption of electrolyte increases by 30%, and a high-concentration lithium salt system needs to be matched.

Typical applications: Long-range batteries for high-end electric motorcycles, micro power supplies for wearable devices.

Lithium titanate (Li₄Ti₅O₁₂) : An extremist for safety and longevity

Crystal structure: Spinel three-dimensional framework, lithium ion diffusion coefficient reaches 2×10⁻⁸ cm²/s (10 times that of graphite).

Core features:

Zero volume strain: Lattice change during charging and discharging is less than 0.3%, and cycle life exceeds 20,000 times.

High safety: The 1.5V working voltage prevents the formation of lithium dendrites and can pass the needle-puncture test.

Ultra-wide temperature range: -40℃ to 60℃, capacity retention rate exceeds 90%.

Performance cost:

The energy density is only 175mAh/g, which is 53% lower than that of graphite.

The voltage platform leads to a 20% decrease in the overall energy density of the battery.

Typical applications: start-stop power supplies for special vehicles, frequency regulation energy storage systems for power grids.

Conclusion

From the layered mazes of graphite to the silicon-based nanouniverse, every evolution of anode materials has broken through the shackles of physical laws. In the future, when lithium metal anodes are perfectly combined with solid electrolytes and when biomass carbon materials rewrite the rules of sustainable energy storage, humanity may bid farewell to "range anxiety" completely.

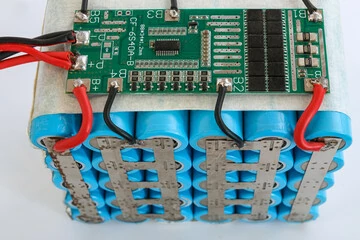

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!