Lithium battery separator: a nano-barrier that guards safety

main content

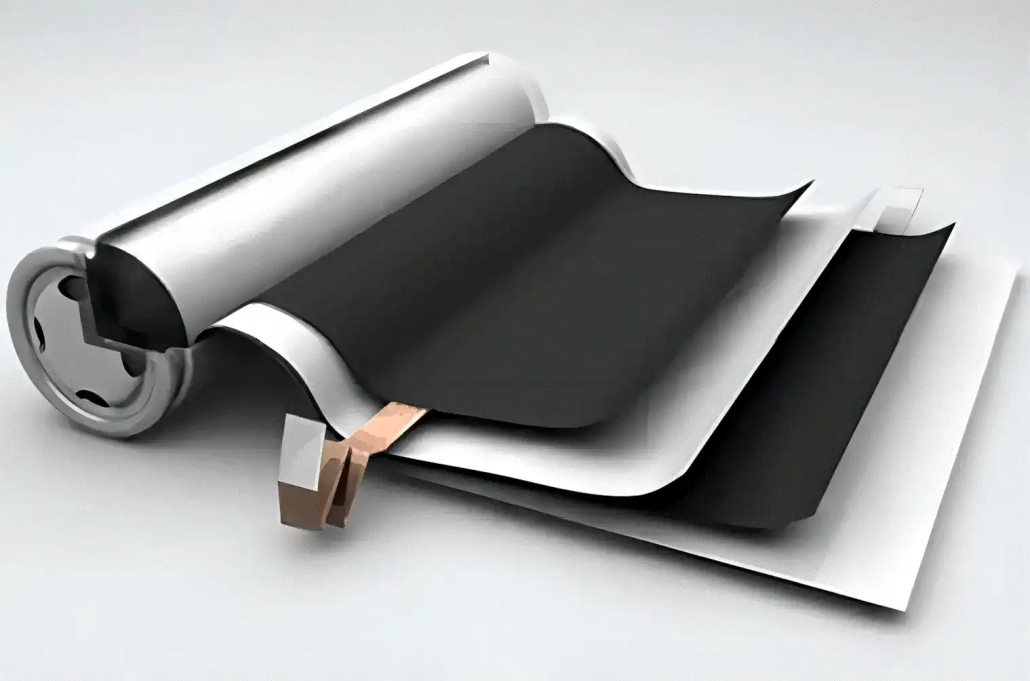

In the complex system of lithium battery, diaphragm is the key component to ensure safety and performance. The thin film, which is only 5-25 microns thick, is designed to block direct contact between positive and negative electrodes while allowing lithium ions to pass through efficiently. With the improvement of battery performance requirements for electric vehicles and energy storage systems, diaphragm technology has become a research hotspot in the field of materials science and engineering. This paper will analyze the core technology of lithium battery separator from three dimensions of material properties, functional principles and technological innovation.

1. Polyolefin diaphragm: classic material system

Polyolefin materials dominate the market due to their excellent chemical stability and controlled pore structure:

Polyethylene (PE) : through the dry unidirectional stretching process to form micropores, porosity 40%-50%, pore size 0.1-1 microns. Its melting point is about 130 ° C, triggering the obturator effect at 135 ° C, blocking ion transport to prevent thermal runaway.

Polypropylene (PP) : the diaphragm aperture prepared by wet process is more uniform, the melting point is increased to 160℃, and the mechanical strength is 20% higher than that of PE, but the infiltration of the electrolyte is slightly weaker.

Multi-layer composite structure: PP/PE/PP three-layer design combines the low melting point of PE and the high strength of PP, and improves the thermal stability by 30%.

2. Ceramic coated diaphragm: safety performance upgrade

The coating of 2-4 micron inorganic ceramic layers (such as Al₂O₃ and SiO₂) on the surface of polyolefine-based films has achieved three breakthroughs:

High temperature resistance: the thermal shrinkage rate is reduced from 90% of PE to 5% at 200℃ to avoid internal short circuit caused by high temperature melting;

Mechanical strength improvement: ceramic particles make the diaphragm puncture strength reach 500gf (conventional PE is 200gf), effectively inhibit lithium dendrite penetration;

Interfacial stability optimization: the ceramic layer adsorbs electrolyte decomposition products, and the cycle life is extended to more than 800 times.

Conclusion

From the industrial base of polyolefin to the technological leap of ceramic coating, the development history of lithium battery separator confirms the role of material innovation in promoting energy technology.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!