Function principle of lithium battery separator technology

main content

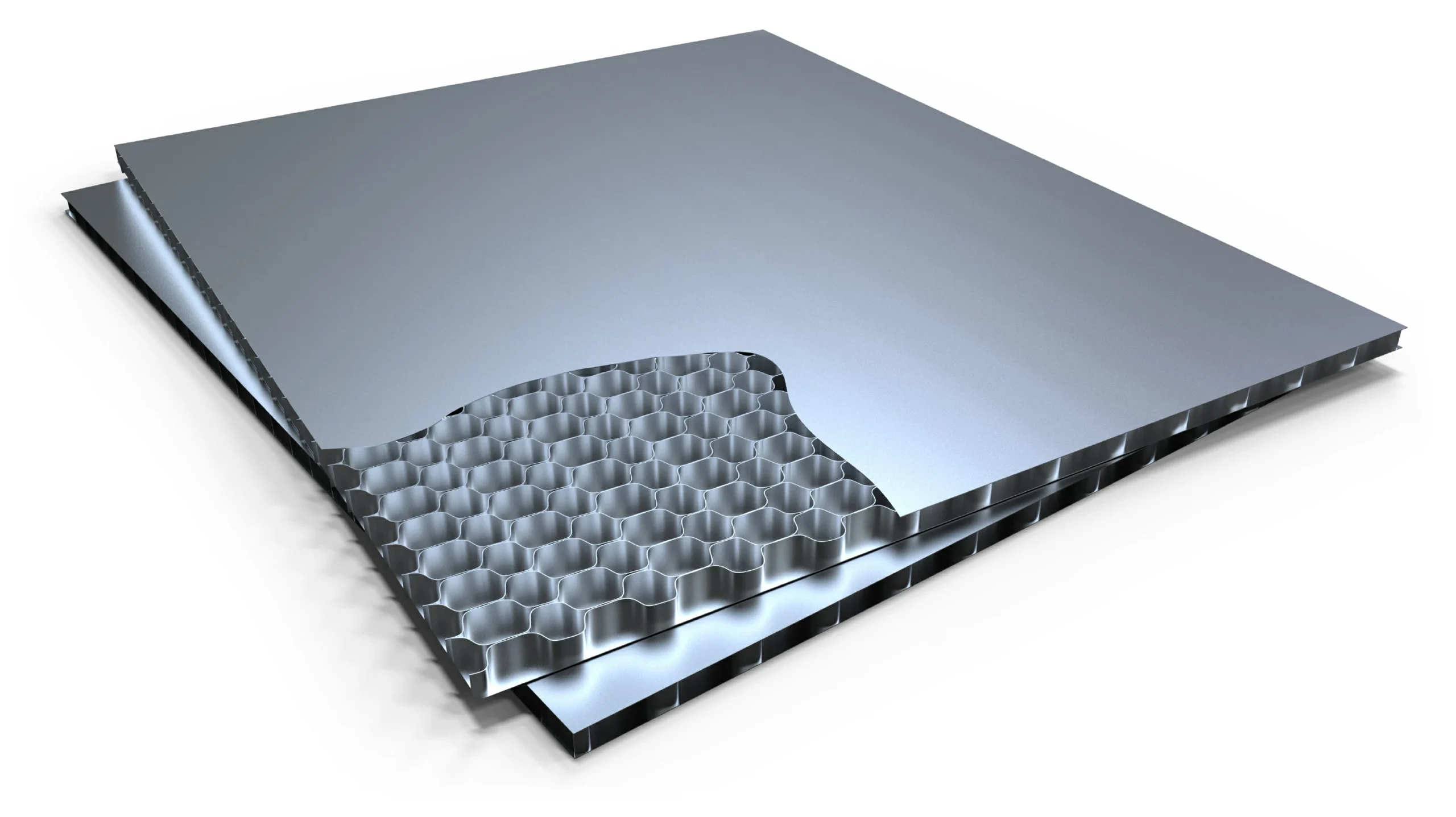

In the complex system of lithium battery, diaphragm is the key component to ensure safety and performance. The thin film, which is only 5-25 microns thick, is designed to block direct contact between positive and negative electrodes while allowing lithium ions to pass through efficiently. With the improvement of battery performance requirements for electric vehicles and energy storage systems, diaphragm technology has become a research hotspot in the field of materials science and engineering. This paper will analyze the core technology of lithium battery separator from the dimension of functional principle.

1. Ion conduction mechanism

The separator establishes a lithium ion transport path through nanoscale pores, and its performance is determined by the following parameters:

Porosity: 40%-60% porosity is the ideal range, too high will reduce the mechanical strength, too low will increase the ion migration resistance;

Pore size distribution: 0.1-1 micron pore size can not only prevent the penetration of electrode particles, but also ensure that the lithium ion flux of 0.8-1.2mA/cm²;

Tortuosity: The tortuosity of the passage affects the transmission efficiency. The advanced diaphragm reduces the tortuosity from 2.5 to 1.8 through the through-hole design.

2. Thermal security protection mechanism

Separator achieves active protection through phase transition response:

Closed cell effect: PE material melts in the crystalline zone at 135℃, the pore closes to block the current, and the response time is less than 1 second;

Ceramic layer thermal barrier: alumina coating thermal conductivity of 30W/m·K, can quickly disperse the local hot spot, delay the heat spread speed.

3. Electrolyte infiltration optimization

Surface modification technology improves electrolyte compatibility:

Plasma treatment: Hydroxyl (-OH) was introduced on the surface of the diaphragm, the contact Angle was reduced from 110° to 30°, and the infiltration time was shortened to 15 seconds.

PVDF coating: Polyvinyliserin fluoride coating enhances chemical stability to high voltage electrolyte (e.g. LiPF₆).

Conclusion

From the industrial base of polyolefin to the technological leap of ceramic coating, the development history of lithium battery separator confirms the role of material innovation in promoting energy technology.

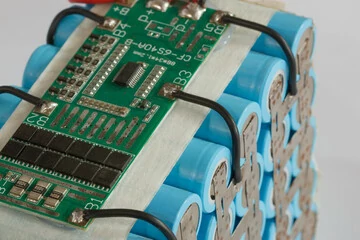

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!