Drone Battery Technologies

Drone battery technology has undergone significant evolution, transitioning from early Nickel-Cadmium (NiCd) and Nickel-Metal Hydride (NiMH) systems to the modern dominance of Lithium Polymer (LiPo) batteries. While NiCd and NiMH technologies are now obsolete for mainstream applications, their historical significance provides valuable insights into battery development. Below is a detailed comparison of these three battery types.Drone battery technology has undergone significant evolution, transitioning from early Nickel-Cadmium (NiCd) and Nickel-Metal Hydride (NiMH) systems to the modern dominance of Lithium Polymer (LiPo) batteries. While NiCd and NiMH technologies are now obsolete for mainstream applications, their historical significance provides valuable insights into battery development. Below is a detailed comparison of these three battery types.

Evolution of Battery Technologies

Chemistry: Utilizes lithium-ion migration between cathodes (e.g., lithium cobalt oxide or ternary materials) and anodes (e.g., graphite or silicon-based materials).

Advantages:

o Energy density: 200-300 Wh/kg (3× higher than NiMH).

o Voltage: 3.7V per cell, configurable as 3S-6S packs (11.1-22.2V).

o Weight: 40-50% lighter than NiMH batteries.

Applications: Consumer drones (e.g., DJI series), FPV racing, industrial inspection.

Drawbacks: Thermal runaway risks (requires BMS protection), cycle life of 500-800 cycles.

Chemistry: Relies on redox reactions between nickel hydroxide cathodes and hydrogen-absorbing alloy anodes.

Historical Role:

o Energy density: 60-120 Wh/kg (1/3 of LiPo).

o Voltage: 1.2V per cell, requiring 10 cells for 12V systems.

o Eco-friendliness: Cadmium-free, >90% recyclability.

Applications: Early drones (pre-2010), low-cost toy drones.

Drawbacks: Significant memory effect, high self-discharge (30% monthly loss), bulky design.

Chemistry: Nickel hydroxide cathodes and cadmium anodes with potassium hydroxide electrolyte.

Legacy Features:

o Energy density: 40-60 Wh/kg (obsolete).

o Voltage: 1.2V per cell with flat discharge curves.

o Durability: 1,000-2,000 cycles (sole advantage).

Historical Use: Industrial/military drones (1980s–2000s).

Drawbacks: Cadmium toxicity (banned under EU RoHS), severe memory effect, poor low-temperature performance.

Conclusion

Lithium Polymer batteries dominate the drone industry due to their high energy density (300 Wh/kg), lightweight design (50% lighter than NiMH), and absence of memory effects. NiMH batteries remain limited to low-end applications, while NiCd batteries have been phased out globally due to cadmium toxicity. The future will solidify LiPo’s dominance, with advancements like solid-state batteries (>400 Wh/kg) further enhancing performance.

Recommendations:

• Drone users: Prioritize LiPo batteries from reputable brands (e.g., Tattu, DJI).

• Researchers: Study NiCd/NiMH systems for historical context.

• Environmental advocates: Promote LiPo recycling (current rate <5%).

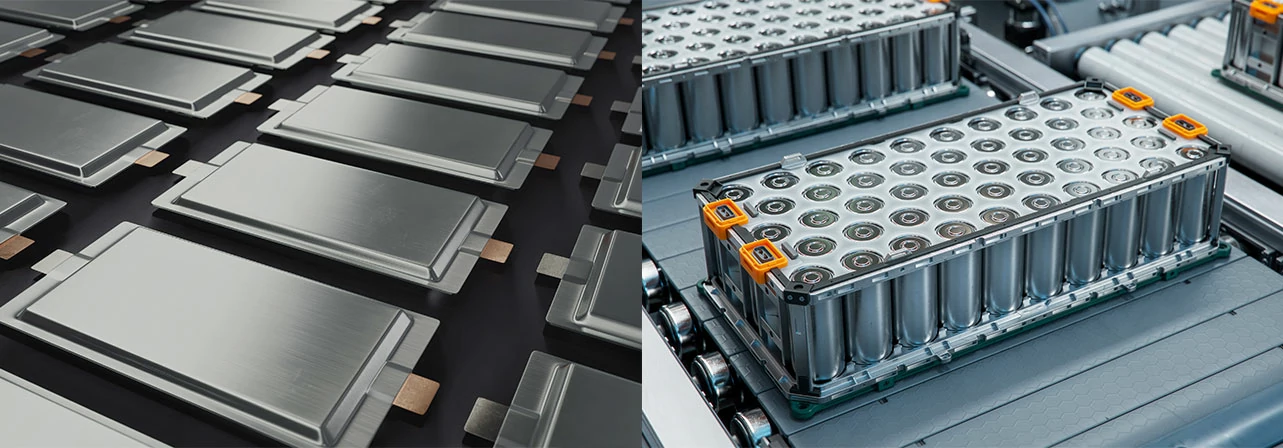

UAV DRONE battery

Enov UAV battery has the most advanced UAV battery new technology, it has a lightweight structural design, ultra-high energy density, stable continuous discharge, customized ultra-high instantaneous discharge, wide temperature working range, stable charge and discharge, battery materials can choose high nickel terpolymer positive/silicon carbon negative material system combined with semi-solid battery technology. Or choose a more mature application of more UAV lithium battery technology, available UAV battery nominal voltage 3.7V, capacity 18.0Ah ~ 30.0Ah, support 10C continuous discharge and 120C pulse discharge (3 seconds). With ultra-high energy density (220-300Wh/kg) as its core advantage, Enov UAV batteries can meet the needs of long-term endurance scenarios such as plant protection drones and transport drones, while maintaining stable emission performance in extremely low temperature environments (-40℃).

Other products

START-STOP LITHIUM BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!