Structural design of positive electrode material

main content

As the core component of lithium battery, anode material directly determines the energy density, cycle life and safety of the battery. It is like a sophisticated ion exchange station, which completes the mutual conversion of chemical energy and electric energy through the embedding and detaching of lithium ions during the charging and discharging process. Currently, the mainstream technology routes include lithium iron phosphate (LiFePO₄), ternary materials (NCM/NCA) and lithium manganate (LiMn₂O₄), each of which seeks to strike a balance between safety, performance and cost. In this article, we will unravel the scientific mysteries behind anode materials from the structural design.

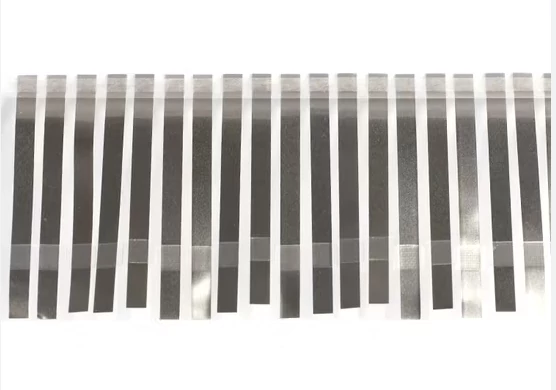

Aluminum Foil Collector

The Mystery of Conductive Skeleton The positive active material is uniformly coated on the surface of 10-20μm-thick aluminum foil through binder (e.g., PVDF). The conductivity of aluminum (3.5×10⁷ S/m) is 60% of that of copper, but its lightweight characteristics can reduce the overall weight of the battery. The surface roughness is controlled at 0.5-1.5 μm to ensure firm attachment of the active substance.

Porous Electrode Layer: Ionic Highway

Thickness control: 80-120μm coating thickness balances the ion transport efficiency and electrode mechanical strength, and over-thickness will lead to lithium ion diffusion obstruction (20% increase in polarization);

Porosity optimization: 30%-40% porosity to form nanoscale pores (50-200nm in diameter), which ensures electrolyte wetting and maintains structural stability;

Conductive network: add 3%-5% of acetylene black or carbon nanotubes to construct a three-dimensional conductive skeleton, and the electron migration rate is enhanced to 1×10-³ S/cm.

Micro-morphology regulation

Spherical particles (5-15 μm in diameter) prepared by spray-drying method can improve the compacted density (lithium iron phosphate up to 2.6 g/cm³), while nanoscale surface coating (e.g., 2 nm alumina layer) can inhibit the dissolution of transition metals and reduce the high-temperature capacity decay rate by 40%.

Conclusion

From the stable fortress of olivine structure to the energy peak of layered oxides, every breakthrough of anode materials is rewriting the boundary of human energy utilization. In the future, with the rise of new systems such as sodium-ion batteries and lithium-sulfur batteries, anode materials will not only be a carrier of energy, but also a technological bridge connecting sustainable energy and zero-carbon society.

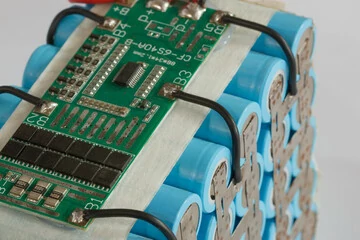

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!