Drone Battery Testing Methods:

Ensuring Safety, Efficiency, and Innovation

Drone Battery Testing Methods: Comprehensive Insights for Optimal UAV Performance

As drones revolutionize industries from logistics to agriculture, reliable battery performance remains critical.

Drone battery testing methods ensure these power sources meet rigorous safety, efficiency, and durability standards. This guide explores six core testing categories—basic performance, environmental adaptability, safety reliability, functional logic, system compatibility, and data-driven predictive analytics—to highlight their role in advancing UAV technology.

Six core test dimensions

Basic performance testing evaluates core metrics like capacity, discharge rates, and voltage stability. For instance, constant and variable power load tests simulate real-world scenarios to measure energy output consistency.

Advanced models predict discharge curves with minimal error, ensuring accurate state-of-charge estimations. These tests also validate internal resistance and charge cycles, providing benchmarks for battery lifespan and operational efficiency.

Moreover, standardized protocols (e.g., ISO 8846) ensure compatibility with marine and aviation safety norms, while coulomb counting tracks energy flow to prevent overestimation or underestimation of capacity.

Drones often operate in harsh environments, making temperature, humidity, and vibration resistance vital. Thermal stress cycling tests expose batteries to rapid temperature fluctuations (-20°C to 60°C) to assess performance degradation. Similarly, vibration tests mimic airborne turbulence to identify mechanical weaknesses in battery casings or connections.

Highly Accelerated Life Testing (HALT) accelerates failure detection by applying extreme stresses beyond typical operating limits. This method ensures batteries withstand prolonged exposure to desert heat, polar cold, or tropical humidity without compromising functionality.

Safety testing focuses on preventing catastrophic failures like thermal runaway or explosions. Short-circuit simulations measure how batteries respond to sudden electrical faults, while thermal shock tests expose cells to rapid temperature spikes (up to 130°C) to evaluate stability.

Additionally, puncture and crush tests replicate physical damage scenarios, ensuring protective casings prevent electrolyte leaks. Compliance with standards like UN 38.3 for lithium-ion batteries guarantees safe transportation and operation under stress.

Modern drone batteries integrate smart management systems (BMS) for real-time monitoring. Functional logic tests verify features like overcharge protection, low-voltage alerts, and balancing algorithms. For example, AI-driven BMS platforms autonomously reroute power during hardware degradation or optimize charging patterns based on usage history.

These tests also validate communication protocols between batteries and drones, ensuring seamless data exchange for mission-critical adjustments.

Batteries must align with a drone’s power demands and hardware. System compatibility tests evaluate electrical interfaces, weight distribution, and thermal management. For instance, integration testing checks if a battery’s voltage curve matches the drone’s propulsion system without causing voltage sag during peak loads.

Electromagnetic compatibility (EMC) tests further ensure batteries don’t interfere with onboard navigation or communication systems, adhering to aviation safety regulations.

Predictive analytics leverages historical performance data to forecast failures. Machine learning models analyze variables like charge cycles, temperature exposure, and voltage drops to predict capacity fade or sudden malfunctions. For example, algorithms trained on thousands of flight logs can alert users to replace batteries before critical missions.

Real-time monitoring tools also track anomalies during flights, enabling adaptive power management. Such systems reduce downtime by 30% in industrial applications, according to recent case studies.

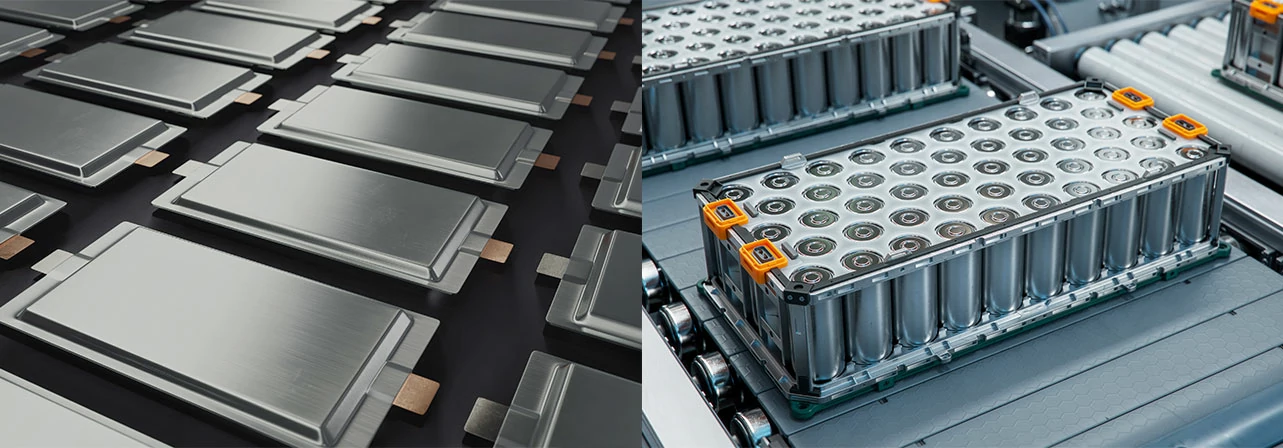

Packaging System Technology Evolution Trends

From validating basic metrics to harnessing AI for predictive maintenance, drone battery testing methods are pivotal in advancing UAV reliability and safety. These protocols not only extend battery lifespans but also ensure compliance with global standards, fostering innovation across sectors. As technology evolves, integrating smarter testing frameworks will drive the next wave of efficient, resilient drone operations.

UAV DRONE battery

Enov UAV battery has the most advanced UAV battery new technology, it has a lightweight structural design, ultra-high energy density, stable continuous discharge, customized ultra-high instantaneous discharge, wide temperature working range, stable charge and discharge, battery materials can choose high nickel terpolymer positive/silicon carbon negative material system combined with semi-solid battery technology. Or choose a more mature application of more UAV lithium battery technology, available UAV battery nominal voltage 3.7V, capacity 18.0Ah ~ 30.0Ah, support 10C continuous discharge and 120C pulse discharge (3 seconds). With ultra-high energy density (220-300Wh/kg) as its core advantage, Enov UAV batteries can meet the needs of long-term endurance scenarios such as plant protection drones and transport drones, while maintaining stable emission performance in extremely low temperature environments (-40℃).

Other products

START-STOP LITHIUM BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!