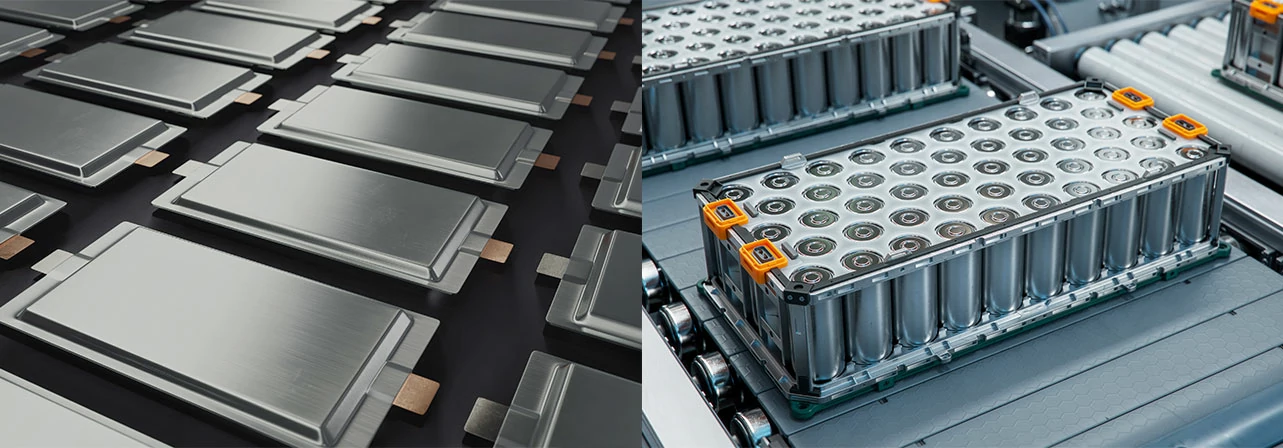

Drone Battery Packaging Innovations: Optimizing Safety and Performance for UAVs Drone battery packaging innovations are redefining UAV performance by combining rugged structural frameworks, adaptive thermal regulation, and intelligent monitoring systems. These advancements ensure operational safety, extended flight times, and resilience in extreme environments. This article explores five critical subsystems transforming modern drone battery design.

Integration Value of Battery Packaging Systems

The foundation of drone battery packaging lies in its structural integrity. Reinforced polymer casings with rubberized shock absorbers protect cells from vibrations and crashes during high-speed maneuvers or rough landings.

For instance, commercial batteries like the DJI BWX170-2000-22.2 utilize laser-welded 6S1P configurations encased in impact-resistant ABS plastic, ensuring stability under mechanical stress. Modular designs also allow easy integration with diverse drone frames, balancing weight distribution without compromising payload capacity.

Efficient heat dissipation is vital for maintaining battery longevity and preventing thermal runaway. Advanced solutions integrate phase-change materials (PCMs) like paraffin wax and graphene-enhanced heat spreaders to absorb excess heat during rapid discharge.

Grepow’s Tattu Pro series, for example, employs optimized airflow channels and liquid-cooled plates to stabilize temperatures within ±2°C during aggressive flight cycles. Such systems are particularly critical for drones operating in deserts or polar regions, where extreme temperatures degrade conventional thermal management.

Smart battery management systems (BMS) form the core of electrical safety. Multilayer safeguards include MOSFET-controlled charge/discharge cycles, voltage balancing circuits, and short-circuit detection algorithms.

High-end BMS modules, such as those in AUVidea’s D200 system, feature CAN bus communication for real-time fault reporting and ISO 26262-compliant fail-safe protocols. These systems automatically isolate defective cells, reducing fire risks by 80% in high-stakes scenarios like industrial inspections or emergency response missions.

To withstand moisture, dust, and corrosive elements, drone batteries incorporate IP67-rated seals and hydrophobic coatings. Rubberized gaskets and hermetically welded joints prevent water ingress during rainy flights or maritime operations.

Grepow’s NMC semi-solid batteries, for instance, use nano-coated casings to resist saltwater corrosion, making them ideal for offshore wind farm inspections. Additionally, self-healing polymers in Mitsubishi prototypes repair minor casing cracks autonomously, minimizing maintenance downtime in harsh environments.

Modern packaging integrates IoT-enabled BMS for seamless drone integration. Bluetooth Low Energy (BLE) and Wi-Fi protocols enable pilots to monitor state-of-charge (SoC), cell health, and temperature via mobile apps.

The Tattu Plus 1.0 series, for example, pairs with AI-driven analytics platforms to predict battery lifespan with 95% accuracy. RFID tagging further simplifies fleet management, allowing automated charging station handshakes and compliance tracking under regulations like the EU Battery Passport.

Packaging System Technology Evolution Trends

From vibration-resistant frames to self-diagnosing BMS, drone battery packaging innovations are pivotal in unlocking UAV potential across industries. These systems not only enhance safety and durability but also enable smarter energy management for logistics, agriculture, and aerial surveillance.

As drone applications expand, next-gen packaging will continue to prioritize lightweight design, regulatory compliance, and seamless integration with evolving UAV technologies.

UAV DRONE battery

Enov UAV battery has the most advanced UAV battery new technology, it has a lightweight structural design, ultra-high energy density, stable continuous discharge, customized ultra-high instantaneous discharge, wide temperature working range, stable charge and discharge, battery materials can choose high nickel terpolymer positive/silicon carbon negative material system combined with semi-solid battery technology. Or choose a more mature application of more UAV lithium battery technology, available UAV battery nominal voltage 3.7V, capacity 18.0Ah ~ 30.0Ah, support 10C continuous discharge and 120C pulse discharge (3 seconds). With ultra-high energy density (220-300Wh/kg) as its core advantage, Enov UAV batteries can meet the needs of long-term endurance scenarios such as plant protection drones and transport drones, while maintaining stable emission performance in extremely low temperature environments (-40℃).

Other products

START-STOP LITHIUM BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!