Motorcycle starter lithium battery charging and discharging chemical reaction

As the core power unit of modern motorcycle, the charge and discharge process of lithium battery is essentially the "migration" and "storage" of lithium ions between positive and negative electrode materials. This electrochemical reaction not only determines the energy density and cycle life of the battery, but also directly affects the low temperature starting performance and instantaneous high current output capacity. This paper will take ternary lithium batteries and lithium iron phosphate batteries as examples, in-depth analysis of their charge and discharge chemical mechanisms, and reveal how to achieve efficient energy conversion in motorcycle applications.

Basic structure and reaction frame of lithium battery

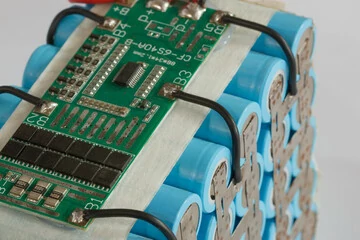

Lithium batteries consist of a positive electrode (containing lithium compounds), a negative electrode (graphite/carbon material), an electrolyte (lithium salts dissolved in organic solvents), and a diaphragm (allowing lithium ions to pass through but blocking electrons). When charging and discharging, lithium ions (Li +) travel between positive and negative electrodes via an electrolyte, while electrons (e⁻) form an electric current via an external circuit, which drives the motorcycle's starting motor.

Charge and discharge reaction of ternary lithium battery

1. Cathode material: lithium nickel-cobalt manganate (LiNiCoMnO₂)

Charging reaction:

In this process, the lithium ions are separated from the layered oxide lattice and embedded into the layered structure of the graphite

Discharge reaction:

The lithium ions migrate in reverse, the positive electrode re-imparts the lithium, and the graphite releases the lithium ions, at which point the electrons flow through the external circuit to the positive electrode, providing the starting current for the motorcycle.

2. Feature advantages

Terpolymer lithium batteries have become the first choice for motorcycle cold starts due to their high energy density (200-250 Wh/kg) and rapid ion migration capability. Its layered structure provides a wider lithium-ion diffusion channel and supports instantaneous discharge rates above 30C.

Charge and discharge reaction of lithium iron phosphate battery

1. Positive electrode material: Lithium iron phosphate (LiFePO₄)

Charging reaction:

The positive olivine structure releases lithium ions, and the negative lithium is intercalated to form graphite intercalation compounds. The stability of olivine structure reduces the risk of material decomposition at high temperatures.

Discharge reaction:

Lithium ions return to the positive lattice, and the graphite layer releases the stored lithium ions to complete the energy output.

2. Feature advantages

The lithium iron phosphate battery has excellent thermal stability (thermal runaway temperature of 270 ° C) and is suitable for high temperature environment. However, its low temperature performance is weak (-10℃ capacity decays to 60%), and it needs to rely on the BMS heating system to improve the cold start performance.

Key chemical phenomena are associated with motorcycle applications

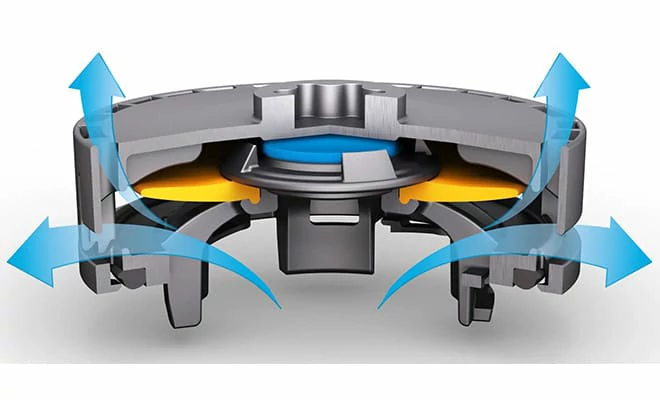

1. Lithium ion diffusion rate: When charging, lithium ions on the negative surface can easily form "traffic congestion" (similar to a car entering a narrow street from a highway), resulting in increased polarization internal resistance. The dynamic cell expands the ion diffusion channel through nanoscale negative electrode materials (such as silicon carbon composite) to improve the high current response speed.

2. Double-edged sword effect of SEI film: When first charged, the electrolyte decomposes on the negative surface to form a solid electrolyte interface film (SEI), which protects the electrode but consumes active lithium ions (capacity attenuation of about 5-10%). High-end motorcycle batteries reduce SEI losses through the pre-lithium process.

3. Temperature and reaction kinetics: At low temperatures, the viscosity of the electrolyte increases and the migration of lithium ions is blocked (the resistance of the electrolyte rises to 10 times that of normal temperature at -20℃). Low temperature ionic conductivity can be improved by using a low viscosity solvent such as vinyl carbonate/dimethyl carbonate mixture.

Conclusion

The essence of the charge and discharge chemical reaction of lithium battery is the reversible insertion and withdrawal of lithium ions in the positive and negative lattice, and its efficiency directly determines the starting performance of the motorcycle. Terpolymer lithium batteries are preferred in cold areas because of their high energy density, while lithium iron phosphate batteries are known for their long life and safety. In the future, solid electrolyte technology is expected to break through the existing lithium-ion diffusion bottleneck, achieve efficient operation in the full temperature range of -40 ° C to 80 ° C, and promote the evolution of motorcycle power systems to a more lightweight and highly reliable direction.

Through precise control of material chemistry and battery management systems, lithium batteries will continue to provide surging and stable starting energy for motorcycles, becoming the core support for the transition to electrification in the era of internal combustion engines.

START-STOP LITHIUM battery

Enov start-stop battery is designed to provide excellent performance for high-demand start-stop vaehicles. It adopts the third-generation intelligent lithium platform architecture to achieve technological breakthroughs in core indicators such as cycle life, environmental adaptability and energy density. Compared with the traditional lead-acid battery system, the energy efficiency is increased by 210%, the cycle life is extended by 8-10 times, and the monthly self-discharge rate is controlled within 3%. Enov's unique low-temperature battery technology makes a breakthrough in achieving stable output in the whole climate domain from -30℃ to 65℃, maintaining more than 90% of the effective capacity release under extremely cold conditions (-30℃), and maintaining 90% of the capacity in high temperature environments (65℃).

The start-stop battery series products cover the mainstream voltage platform of 12V/24V/48V, and support flexible configuration of LFP (lithium iron phosphate) and NCM (lithium nickel cobalt manganese oxide) dual-material system. All models adopt modular design to support customization of different model specifications. Enuo engineering and technical team to provide full cycle technical service support, if you need, please contact us.

Other products

UAV BATTERY

LITHIUM ENERGY STORAGE BATTERY

QUICK INQUIRY

FAQ

Access to high frequency technical questions with one click, get accurate answers on product application, after-sales policy and customization process.

Service and Support

Get the latest product specifications, explore professional OEM/ODM customization services, click to open exclusive technical support and production solutions.

Become a Partner

We sincerely invite resources to interconnect, work together for win-win development, and immediately open a new chapter of strategic cooperation!